Multiscale material characterization and testing

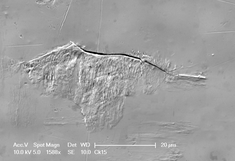

Fracture mechanics and fatigue crack growth

The applied testing equipment allows fracture mechanical characterisation of natural materials und composites under quasi-static loading. Cut-through-tensile splitting strength and specific fracture energy can be determined using the wedge splitting method. A compact test set-up enables in-situ measurement in the environmental scanning electron microscope. Furthermore, measurements of fatigue crack growth rates (FCGR) in the near threshold regime and cyclic threshold stress intensity factors in metals are performed. Very low FCGRs down to 10-14 m/cycle can be determined using ultrasonic fatigue testing equipment. contact: H. Mayer, B. Schönbauer, G. Sinn, S. Tschegg

Micromechanical testing, microindentation

Biological materials are characterized by their relatively low number and simple chemical components arranged in complex structures. These structures are part of more complex higher level architectures. Typical representatives of these construction principles are bone and wood. Therefore, usually it is not sufficient to now the behaviour of these materials at one scale but the properties of these materials have to be measured at different levels of hierarchy and correlated with the information achieved from other scales. Important mechanical properties are tension and compression but also crack initiation and hardness. Hardness can be measured at micro and nanoscale. Kontakt: G. Sinn, H. Lichtenegger

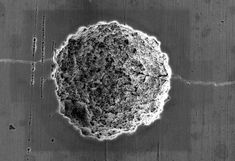

Charcaterization of materials at nanoscale

The study of nanoscale structures and nanocomposite materials is a special focus of the Institute of Physics and Materials Science. Our nanocharacterization laboratory offers a combination of environmental scanning electron microscopy in combination with in-situ deformation and in-situ nanoindentation for position resolved mechanical characterization. Non-destructive x-ray scattering methods (small-angle scattering SAXS, grazing incidence SAXS / GISAXS, wide-angle scattering / XRD) are used to characterize complex nano-structured materials such as wood, bone, CNT composites, nanoparticles, nanoporous materials, aerogels etc. We specialize in combining position resolved methods and develop custom-made additions to our devices. Contact: H. Rennhofer, G. Sinn, H. Lichtenegger

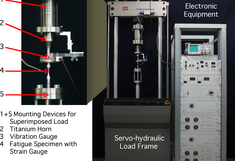

High cycle fatigue

Material fatigue is a damage process where localization of cyclic deformation, the formation of a crack and eventual failure is caused by repeated loading and unloading. Institute research focuses on experimental investigations and descriptions of material behaviour after long service times, after stressing with high numbers of cycles (up to the very high cycle regime) at rather low load amplitudes. Conventional as well as ultrasonic fatigue testing techniques are used in investigations of metallic materials (cast, wrought, PM alloys) and composites used in transportation industry, in power plants as well as in biomedical applications.

Contact: H. Mayer

Development of ultrasonic fatigue testing equipment

High-precision ultrasonic fatigue testing equipment is developed at the institute. New testing capabilities are developed, such as different testing procedures, using different materials and specimen shapes, testing in various environments and advanced analysing techniques.

Some recent developments are: variable amplitude loading with superimposed varying mean loads, ultrasonic torsion vibration with superimposed torsion mean loads, testing of thin sheets, monitoring of fatigue damage using non-linear acoustics, lifetime and fracture mechanics investigations in environmental chambers. Contact: H. Mayer

Characterization of complex natural materials (wood, soil, charcoal, …) by means of infrared spectroscopy

Infrared spectroscopy is a technique allowing to get insight into the molecular structure of materials as well as into interactions on molecular level. The available IR-instrumentation covers a wide range from qualitative to quantitative assessment of mostly organic components (e.g. wood, straw, animal excrements...) up to changes according to different environmental conditions. Besides the common KBr-pellet technique especially ATR is applied for the investigations. For NIR-measurements a fibre-optic probe is available. Futhermore a Hyperspectral Imaging System allows the spatial and spectral visualization of material surfaces and allows the qualitative and quantitative evaluation of materials characteristics. Contact: B. Hinterstoisser