On the Automation and Digitisation of Subtractive Machining with Industrial Robots in Timber Construction. Parameter Studies, Increase in Efficiency and System Integration

SUPERVISOR: Benjamin KROMOSER

PROJECT ASSIGNED TO: Marc PANTSCHAROWITSCH

The share of timber construction within the building industry has been growing worldwide for several years, inter alia due to the positive environmental impact. This leads to the necessity of considerable improving the efficiency of the production processes. A promising approach is the digitalisation of the process chain and the implementation of new production methods.[1] The fabrication and joinery of glulam beams is currently carried out using specialised joinery machines. A potential extension of the variety of the used machines are standard multi-axis industrial robots, such as used in the automotive industry for decades. The overarching aim of the doctoral thesis is to investigate whether and to what extent the possibilities of robotics and digitisation of the process chain can lead to an increase in production efficiency.

Figure 1: BOKU robot laboratory

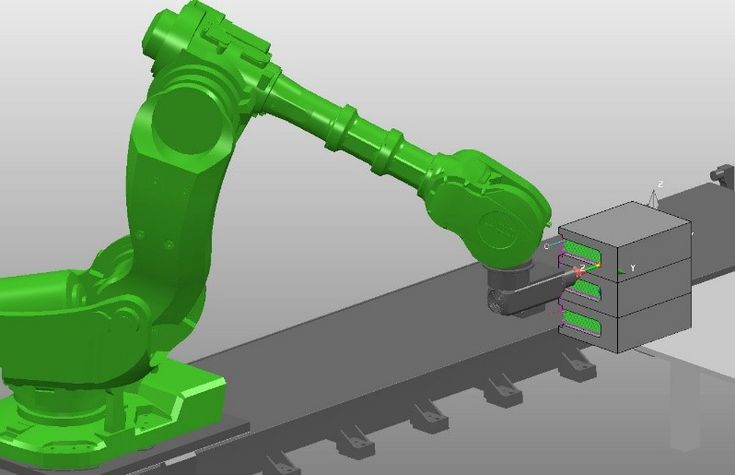

Figure 2: 3D-Batch processing of glued laminated timber beams using an ABB IRB-7600 industrial robot. With machining spindle as effector.

[1] S. Liang, H. Gu, R. Bergman, und S. S. Kelley, „Comparative life-cycle assessment of a mass timber building and concrete alternative“, Wood Fiber Sci., Bd. 52, Nr. 2, S. 217–229, Apr. 2020, doi: 10.22382/wfs-2020-019.