Natural fiber sources and biobased fiber materials

Description

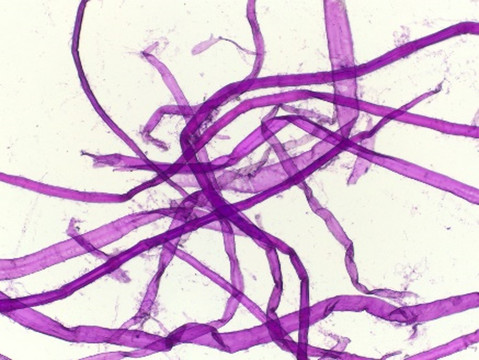

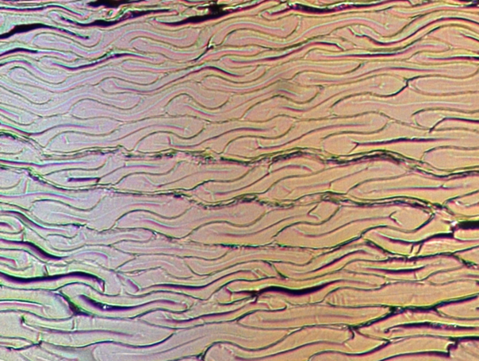

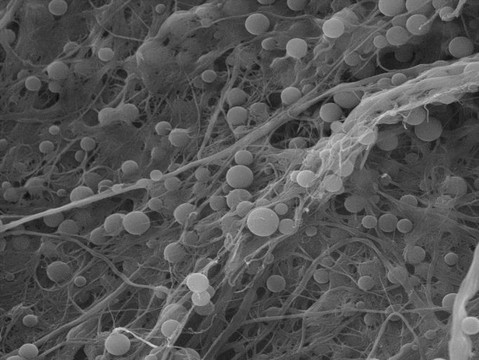

Besides traditional resources like wood, our research covers a wide range of alternative fiber sources including straw, oil palm trunk or sugar beet pulp. The raw materials are processed by appropriate pulping and/or disintegration techniques and characterized in terms of chemical and structural properties. The high tensile strength of cellulose-based fibers enables biobased fiber materials with excellent mechanical qualities. In such a material, fibers may either serve as the only structural element or as a reinforcing component like in polymer matrix composites. For the preparation of high-performance biobased fiber materials we pursue different concepts ranging from nanocellulose-based materials all the way to densified wood materials in which the natural structure of wood is largely preserved.

Contact: Wolfgang Gindl-Altmutter

Research and publications

Nanocellulose from papermaking fines

High-strength cellulose materials by delignification and densification of wood

Lignin as a natural coupling agent in polymer matrix composites

Mechanical reinforcement of particleboard adhesives with fibrillated cellulose

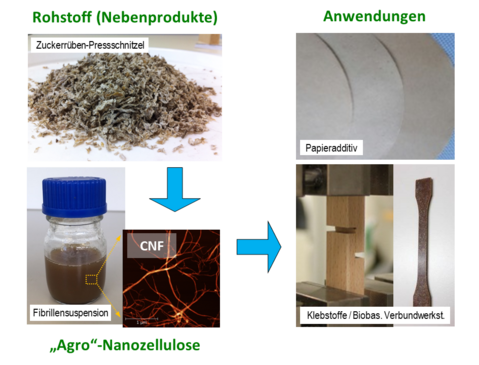

„Agro-Nanocellulose“: Nanocellulose from agroindustry by-products

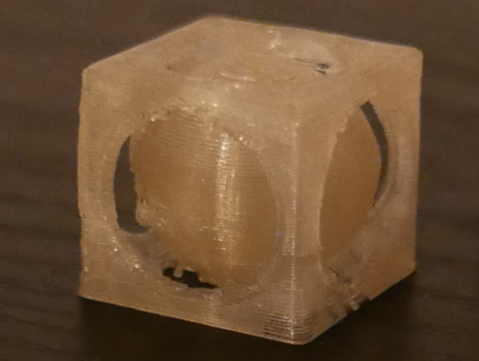

Biobased 3D printing filaments based on polylactide and fibrillated lignocellulose

Theses (since 2015)

Dissertations

Felix Neudecker (ongoing): Upgrading straw to versatile structural materials.

Lukmanul Hakim Zaini (ongoing): Development of bionanocomposite from utilization of inner part of oil palm trunk (IPOPAT) for bioadhesive production.

Anita Tran (2023): Innovative adhesive bonding of load-bearing wood materials at low temperature.

Matthias Jakob (2023): Herstellung und Optimierung eines "grünen" Hochleistungswerkstoffes auf Holzbasis.

Sabine Herzele (2019): Interfaces between lignocellulosic fibers and synthetic polymers.

Stefan Pinkl (2019): Engineering of wood bonding with additives.

Jérôme Colson (2017): Fines for non-paper products.

Eike Alexander Mahrdt (2016): Mikroskopische Charakterisierung der Klebstoffverteilung in Holzwerkstoffen – in Bezug zu mechanischen Holzwerkstoffeigenschaften.

Master theses

Dragoslav Vasovic (ongoing): Fibrillierte Rinde als Klebstoffersatz.

Benedikt Preschern (2020): Innovativer Plattenwerkstoff aus Zuckerrübenschnitzel „Vom Abfall zum Bauprodukt der Zukunft".

Franziska Haller (2020): Mehrlagiger Papierverbundwerkstoff.

Jakob Johannes Gaugeler (2020): Charakterisierung von delignifizierten, komprimierten Furnieren.

Bernhard Ungerer (2019): Synthesis and Characterization of novel Chitin-Cellulose Composites aiming for structural reinforcement.

Gregor Stemmer (2019): Delignifizierung, Verdichtung und Verarbeitung von Fichtenfurnier zu Hochleistungssperrholz.

Victoria Löschenbrand (2019): Verdichtete und imprägnierte Schichtwerkstoffe aus Fichtenfurnieren.

Matthias Jakob (2018): Herstellung und Charakterisierung eines Verbundwerkstoffes aus zum Teil delignifizierten, verdichteten Holz-Chips.

Erich Streit (2018): Herstellung und Charakterisierung von Verbundwerkstoffen aus Lehm und Naturfasern sowie natürlichen Zusätzen.

Daniel Ballner (2017): Microfibrillated cellulose-enabled suspension polymerisation of polystyrene.

Eva-Marieke Lems (2017): Compatibilisation of Microfibrillated Cellulose with Linseed Oil.

Benjamin Arminger (2017): Mikrofibrillierte Zellulose (MFC)- Einfluss von Produktion und Ausgangsstoffen auf die rheologischen Eigenschaften.

Armin Winter (2017): Improvement adhesion and dispersion of microfibrillated lignocellulose compared to pure cellulose in poly(lactic-acid).

Andreas Schindler (2016): Modifikation von Aminoplasten in Holzwerkstoffen.

Wolfgang Kugi (2016): Holzlaufrad / Woodrim Evaluation and optimization of composite wood and fiber-reinforced composite woodrims.

Marcel Kluge (2016): Nanocellulosic fillers for waterborne wood coatings.

Johannes Raffling (2015): Verklebung von Massivholz mit Nanozellulose modifiziertem Klebstoff.

Clemens Schmidberger (2015): Distribution of Adhesive in Particle Boards.

Felix Strangfeld (2015): Modifikation von Nanozellulose zur Einbringung in Öl-basierte Beschichtungen.