04.11.2021 - Individualized Cellulose Nanofibrils for the Production of Super-materials

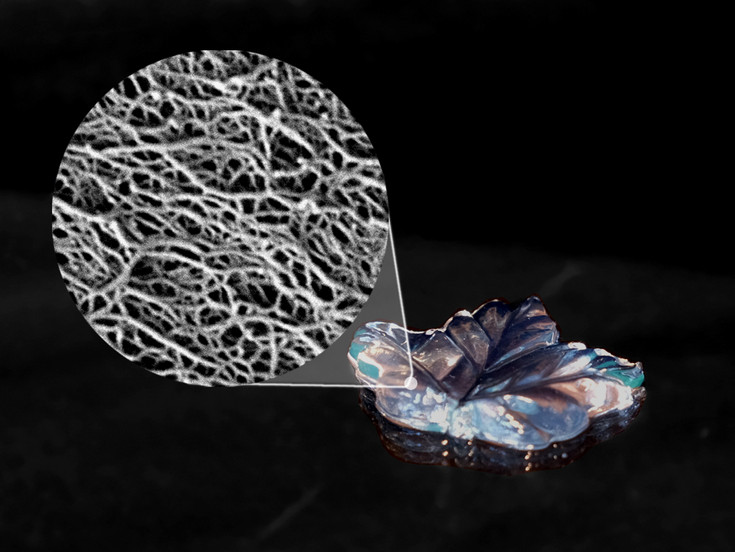

Hydrogel made from native cellulose nanofibrils and electron micrograph of the surface structure (image detail 1 µm) © Marco Beaumont / BOKU

Elementary cellulose nanofibrils are among the strongest known polymer materials. An international team of researchers has now developed a reversible and sustainable chemical process to reveal their full potential.

Plant cellulose consists of a complex structure based on individual cellulose nanofibrils – representing the smallest structural unit to which wood owes its strength and stability. These nanofibrils are thin, with a diameter of just a few nanometers, yet they are among the strongest materials known. Until now, the isolation of these nanofibers has always involved an irreversible chemical process that altered the chemical surface of the fibers - which is a limitation in the development of potential super-materials because it hampers interactions between individual nanofibers, such as in a film or rope.

The Institute of Chemistry of Renewable Resources at the University of Natural Resources and Life Sciences, Vienna, in cooperation with researchers from Canada (University of British Columbia), Finland (Aalto University and University of Helsinki) and Australia (University of Melbourne), has now developed a groundbreaking new method for the isolation of cellulose fibrils with a reversible chemical reaction: the temporary modification can be reversed by a mild post-treatment to recover the native structural constitution. "You can think of it as Lego bricks," Marco Beaumont explains of the process. "We change the surface structure, the construct falls apart and the bricks can no longer be put together properly afterwards. With the method we have developed, we can restore the original condition so that the connecting pieces fit perfectly again."

In this specific case, it means that wood fibers are chemically treated with N-succinylimidazole to isolate the individual cellulose fibrils through introduction of a surface charge. "Our method is particularly mild and sustainable" explains Thomas Rosenau. "Until now, it was always necessary to chemically modify cellulose fibrils in an irreversible way, which also resulted in chemical degradation of the cellulose." The introduced carboxyl groups on the cellulose nanofibrils can be easily removed again by a mild post-treatment. This allows the original chemical and structural interfaces to be reconstituted, which is necessary to develop super-materials. The team at the Institute for Chemistry of Renewable Resources has opened a new avenue with its research, in which the full potential of cellulose as a sustainable building block can be unlocked.

The results were published in the renowned Journal of The American Chemical Society and additionally showcased on the cover of the October issue.

https://pubs.acs.org/doi/abs/10.1021/jacs.1c06502

More photos © Marco Beaumont / BOKU

https://bokubox.boku.ac.at/index.php/#18a9cf2482e78f97b25f1d4200e07af8

Photo 1: Hydrogel made from native cellulose nanofibrils and electron micrograph of the surface structure (image detail 1 µm)

Photo 2: Hydrogels made from native cellulose nanofibrils

Contact:

Prof. Dr. Thomas Rosenau

Institut für Chemie nachwachsender Rohstoffe

Universität für Bodenkultur Wien

thomas.rosenau(at)boku.ac.at

+43 1 47654 77411

Dr. Marco Beaumont

Institut für Chemie nachwachsender Rohstoffe

Universität für Bodenkultur Wien

marco.beaumont(at)boku.ac.at

+43 1 47654 77436

Hydrogels made from native cellulose nanofibrils © Marco Beaumont / BOKU