FFG Project Prefab.Facade

Prefab.Facade – Improving the performance of recyclable, serially prefabricated facade elements

The construction sector is responsible for a significant share of global resource consumption, CO₂

emissions, and waste. Approximately 34 % of global CO₂ emissions and 32 % of energy consumption are

attributable to the construction and operation of buildings. In particular, existing buildings with poor energy

performance offer substantial potential to reduce energy demand through renovation. At the same time,

integrating resource-efficient and circular construction methods, combined with automated

manufacturing, can lower raw material use and environmental impacts while creating new economic

opportunities for the construction industry.

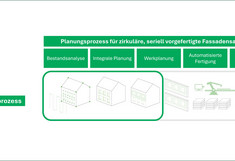

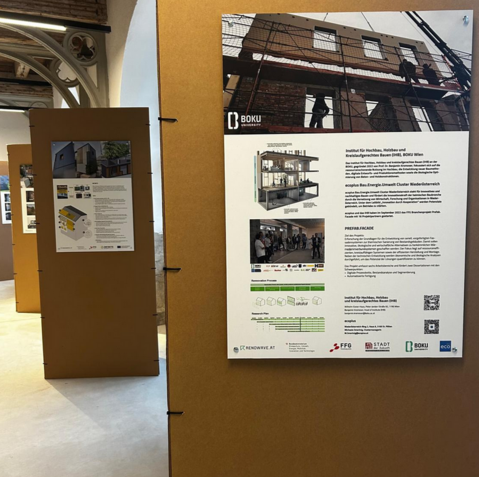

The research project “Prefab.Facade – Performance enhancement of circular, serially prefabricated

façade elements” aimed to establish the basis for developing and broadly deploying modular timber frame

systems for renovation, manufactured in an off-site prefabrication process. The focus was on maximizing

the degree of prefabrication, implementing an end-to-end digital process chain from planning through

fabrication to installation, and optimizing the systems ecologically and economically.

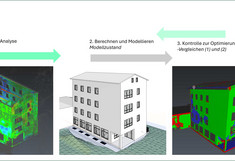

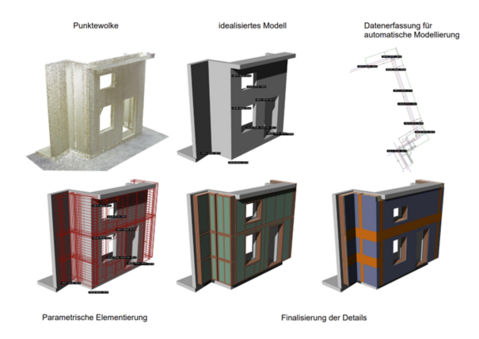

The project investigated innovative approaches to façade renovation, including digital as-built surveying

using laser scanning and drone photogrammetry, the development of optimized layer assemblies, and the

automation of manufacturing with industrial robots. Two full-scale (1 : 1) experimental walls built in the

laboratory enabled practical testing—for example, the installation of façade elements, the evaluation of

mounting systems and efficient inter-module connection techniques. In addition, the minimization of

thermal bridges, seamless ventilated render façades, and various cladding systems were assessed for

practical suitability.

The results show that modular façade systems can achieve significantly higher circularity and lower

environmental impacts than conventional external thermal insulation composite systems (ETICS). Serial

prefabrication shortens construction times, reduces labor requirements, minimizes weather-dependent

work, and improves execution quality. The digital process chain and precise as-built data enable efficient

planning and implementation, while targeted material choices substantially reduce environmental

impacts.

Overall, the investigations provide valuable insights for optimizing construction processes and advancing

sustainable, resource-efficient façade systems that can make a decisive contribution to promoting

circularity and climate neutrality in the built environment.

FFG Prefab.Facade auf BOKU FIS

Final Report:

Partner:

- Projektleitung: ecoplus Bau.Energie.Umwelt Cluster Niederösterreich

- Koppelhuber² und Partner ZT OG

- MAGK Architektur

- VÖZ - Verband österreichischer. Ziegelwerke

- Vinzenz Harrer GmbH

- SIHGA GmbH

- fischerwerke GmbH & Co. KG

- ÖFHF – Österreichischer Fachverband für hinterlüftete Fassaden

- PREFA Aluminiumprodukte GmbH

- Keplinger GmbH

- einszueins architektur ZT GMBH

- Sto Ges.m.b.H.

- nonconform zt gmbh

- Metallica Stahl- und Fassadentechnik GmbH

- Georg Fessl GmbH

- utb Laser und Vermessungstechnik GmbH

- FCP Fritsch, Chiari & Partner ZT GmbH

- O.K. Energie Haus GmbH

Sponsor:

Prefab.Facade is funded by the BMDW and BMK as part of the ‘Collective Research’ instrument of the FFG basic programme.