Structural wood building materials

Description

Wood is one of the oldest building materials in our society and has excellent mechanical properties with comparatively low density. In the research field "Structural wood building materials", we deal with the properties of existing and new wood materials for use as load-bearing components in building construction in combination with their manufacturing processes. The overriding goal is the resource-efficient utilisation of wood as a raw material and its targeted use. The investigation of a wide variety of starting assortments as well as established and potential wood species of the future form the basis of current research priorities.

Contact: Maximilian Pramreiter and Johannes Konnerth

Research and publications

How much wood do we need for 1m³ Cross Laminated Timber?

"We need to start using our wood more efficiently"

Innovative mechanical disintegration technologies for wood

Engineering of material properties through the selection of adhesives using the example of a novel wood-based material

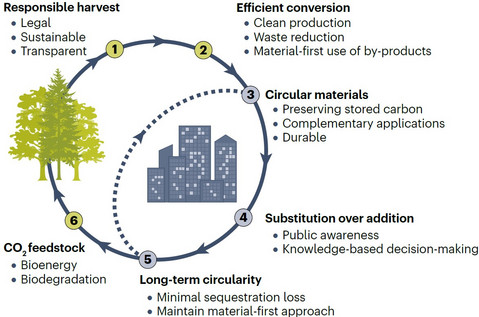

A blueprint for global initiatives of bio-based materials

A plea for the efficient use of wood in construction

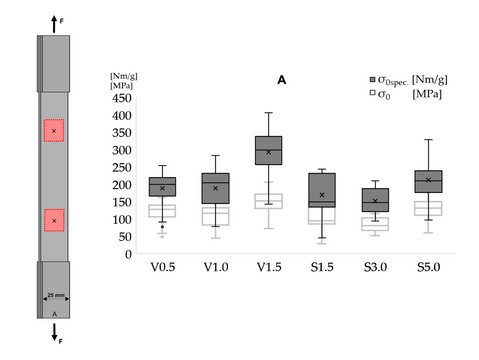

Influence of thickness on the tensile strength of birch veneer at different loading angles

Non-destructive characterisation of veneers for structural composites

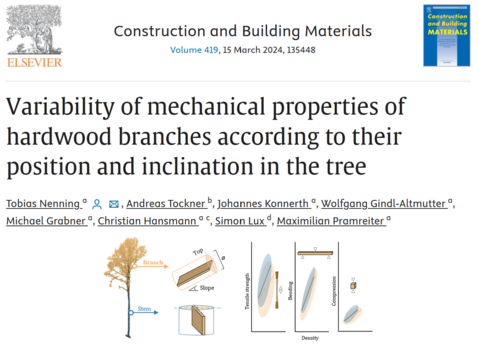

Are hardwood branches as powerful as stem wood?

A systematic review of strand-based engineered wood products for construction: standard test methods and mechanical properties

The Utilization of European Beech Wood (Fagus sylvatica L.) in Europe

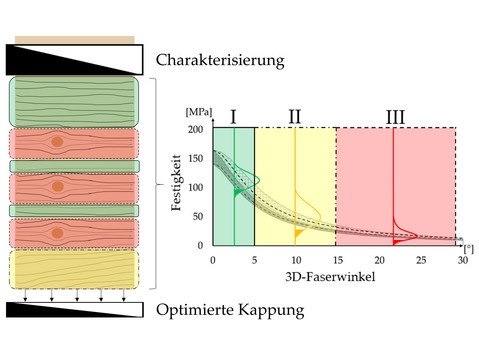

Novel wood-based material based on naturally optimised wood particles

Events

10th BOKU Sustainability Day

On 20th of November 2024, the 10th BOKU Sustainability Day took place in Vienna under the motto ‘Climate Minds - active and resilient against fear and powerlessness’. The focus was on the role of research and education in overcoming psychological barriers, promoting a climate-positive mindset and generating positive impulses for action.

We are pleased to be among the three nominees for the BOKU Sustainability Award in the publication category with results from the research projects UniStrand (FFG 893351) and StrongHardwood (FTI20-003). The presentation can be viewed here.

"Science goes Public 2024" sheds light on climate research in Lower Austria

On 7 November 2024, the event ‘Science goes Public 2024’ took place at the APA Press Centre, organised by the Gesellschaft für Forschungsförderung Niederösterreich (GFF NÖ). The hybrid event focused on seven basic research projects that were funded by the state of Lower Austria as part of the FIT-Call Climate Change 2019 and 2020. The project "StrongHardwood" took first place. The entire event can be viewed here.

Panel discussion: HOLZBAU - Innovativ oder am Holzweg (in German)?

Organised by BOKU students, Uni.-Prof. Dipl.-Ing. Dr. Johannes Konnerth discussed current innovations and future developments in the field of timber construction with renowned industry representatives and scientists. To be found at: https://youtu.be/aUpEThWj834

Projects

Strong Hardwood (ongoing)

Climate change is one of the key factors driving an adaptation of species composition of Austrian forests, diminishing the proportion of softwood in favour of hardwood, particularly beech and oak, which are more resistant to drought and ensuing calamities. Since beech and oak are fundamentally different from the currently dominating softwood spruce in terms of their technological properties, new approaches to boost high-value hardwood utilisation are urgently needed. The present proposal suggests splitting as a means to minimise fibre deviations on hardwood from low-quality branch-wood. Furthermore, split macro-fibrous elements will be straightened with the aid of thermally assisted plasticisation in steam and densified to form high-value, straight fibre beam elements capable of serving as structural elements e.g. in construction or automotive. This highly material-efficient utilisation concept for low-value hardwood provides numerous benefits in that it enables a high proportion of bio-based material utilisation also in future, supporting the continuous competitiveness of the forest-based sector in times of climate change.

Contact: Maximilian Pramreiter

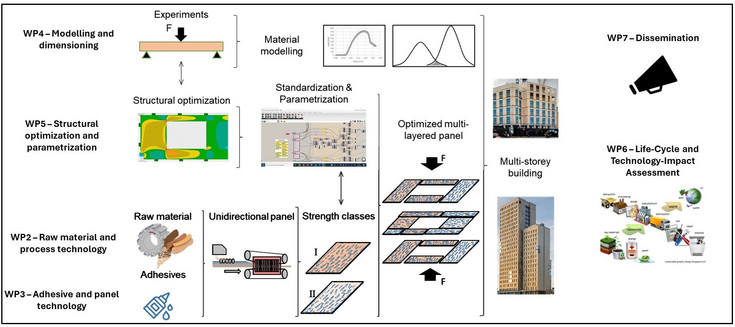

UniStrand (ongoing)

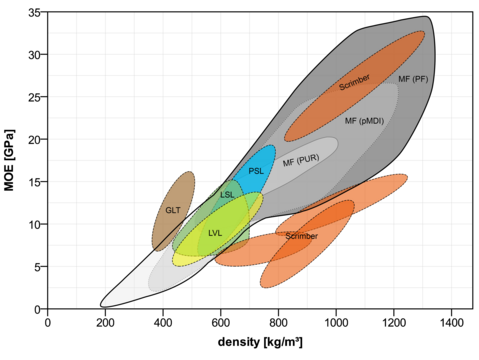

In recent years, timber construction has been able to demonstrate its suitability for multi-storey buildings through various lighthouse projects (e.g. HoHo, LCT ONE, etc.). The utilization of wood in the construction sector not only leads to a substitution of energy-intensive raw materials with simultaneous carbon storage, but can also satisfy the enormous additional demand for building materials. A significant increase in the utilization efficiency of the resources used is just as inevitable as efficient construction methods and dimensioning of the components. Currently, successful timber construction products such as cross laminated timber (CLT) are predominantly based on softwood lumber and have a low raw material yield (30-40%) due to the production process. The "UniStrand" project is intended to investigate the technological and design fundamentals for a (approx. 7-20cm) thick, panel-shaped, wood-based material for multi-storey, structural building applications. The starting material will be long, thin wood particles (strands), which can be produced with a high raw material yield (over 75%). Mainly hardwood assortments or combinations of softwood and hardwood are to serve as raw material. Unidirectionally oriented strands will be bonded together to form UniStrand boards of different densities, a predictable intermediate product with improved mechanical properties compared to already established strand-based products (oriented strand board, laminated strand lumber). Finally, the required stability and material thickness of the layered wall and ceiling elements will be achieved by crosswise layer bonding of the strand-boards. The combination of a numerical design optimization of the finished elements, coupled with an application-oriented cutting pattern, enables the production of targeted elements that use

high-performance panel material only where this is statically required. The results of the project are continuously evaluated by a process-oriented life cycle assessment (LCA) and a technology impact analysis. The overall vision of the project is to form the basis for a large-scale industrial implementation and pave the way for a resource-efficient wood building material of the next generation.

Contact: Maximilian Pramreiter und Johannes Konnerth

Theses

Dissertations

Simon Lux (ongoing): Strip-like laminations for use in structural wood products

David Obernosterer (ongoing): Development of a homogenised solid wood lamella for hybrid glulam beams made of softwood and hardwood (TU Graz)

Lukas Malzl (ongoing): Investigation of alternative wood species and optimized processes for strand-based unidirectional wood panels for mass timber materials.

Tobias Nenning (ongoing): Structural building materials based on hardwood branches.

Master theses

Christoph Kurz (ongoing): Alternative Zerteilungstechnologie für Laubastholz

Niklas Bugelnig (ongoing): Ressourceneffizienz etablierter Auftrennprozesse von Rundholz.

Raphael Kerschbaumer (2025): Cross-laminated timber – evaluation and identification of barriers to mass timber market growth in the DACH-region

Agnes Spranz (2024): Characterisation of reaction wood in hardwood branches

Jakob Wassermann (2024): Mechanical properties of a wood composite based on hardwood branches

Johannes Kircher (2024): Characterisation of selected properties of finger joints

Nikolaus Pilz (2023): Evaluierung der Leistungsfähigkeit einer mehrlagigen Holzbauplatte auf OSB-Basis.

Stefan Höchtl (2022): Formoptimierte Holzbauträger: Evaluierung eines analytischen Modells auf Basis von Realversuchen.

![[Translate to English:] Christoph Gruber | BOKU University](/fileadmin/_processed_/b/c/csm_BOKU_Nachhaltigkeitspreis_2024_7c4ddf1a26.png)