I/O-Gas: Integration and optimization of the production of renewable gas from biogenic residues

The cooperative research project I/O-Gas is researching and further developing the thermochemical conversion of biogenic residues into synthetic natural gas for grid feed-in and the appropriate integration of these processes into a sustainable Austrian energy system

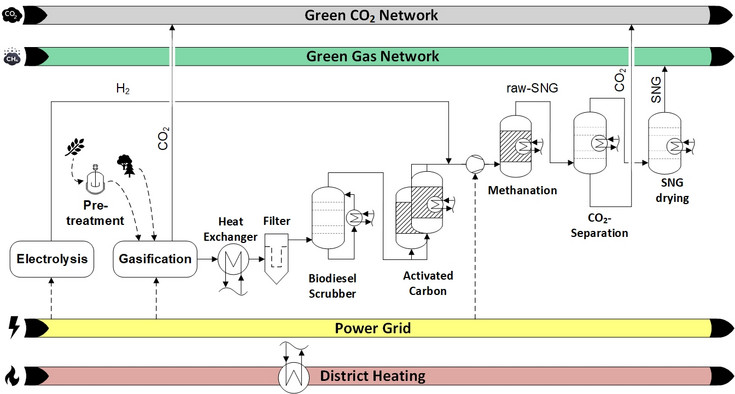

The process flow diagram of the I/O-Gas project, in which fuels are pretreated using various thermochemical processes such as hydrothermal carbonization and pyrolysis so that they can then be converted more efficiently into renewable gas. The process steps of fuel pretreatment, gas production, gas purification, and methanation are optimized. Surplus electricity can be used to support gas production or to produce hydrogen via electrolysis, which can be mixed with product gas. The renewable gas produced is fed into the green gas grid, CO₂ can be separated, and surplus heat can be integrated into a district heating network.

As part of the Green Deal, greenhouse gas emissions in the EU are to be reduced by at least 55% by 2030 compared to 1990 levels. The Renewable Gas Act (EGG) is proposed in Austria as a key contribution to achieving these targets. According to the resolution passed by the Council of Ministers on February 21, 2024, 9.75% or at least 7.5 TWh of fossil natural gas is to be replaced annually by nationally produced renewable gas by 2030 - in comparison, consumption in 2022 was around 85 TWh. From 2024, annually increasing green gas quotas are to be implemented, which must be guaranteed by the suppliers - in the event of non-compliance, a compensation payment of €150/MWh is planned. Gasification in dual fluidized bed (DFB) is a state-of-the-art process for converting woody biomass into product gas and using it to generate electricity and heat. The product gas from DFB gasification is considered very suitable for the production of synthetic natural gas (SNG) due to the comparatively high H2/CO ratio, the high CH4 content and the absence of N2 dilution. Projects for SNG production from woody biomass in Güssing, AT (1 MWSNG), Gothenburg, SE (20 MWSNG) and Lyon, FR (500 kWSNG) have demonstrated the technical feasibility. Despite this, the technology has not yet been successfully implemented. The biggest issues to be resolved in the course of the I/O-Gas project using experimental, analytical and simulative approaches, can be divided into the following sub-processes: 1. Gasification: The use of biogenic residues with low ash melting temperatures and high volatile content and the long-term behavior on downstream process steps with regard to deposits of tar and inorganic components has not been sufficiently researched. Suitable pre-treatment processes and specific concepts for feedstocks with high moisture content as well as seasonal and decentralized biomass are lacking. 2. Gas cleaning: For the use of biogenic residues, it is unclear what concentrations of impurities are to be separated and how usually hardly relevant elements (e.g. halides) are separated with gas cleaning. It is also unclear how the existing chain can deal with the higher concentrations of certain impurities. Significant increases in efficiency are also possible in the regeneration of these gas cleaning stages. 3. SNG production: The methanation (multi-stage adiabatic fixed-bed cascade) and treatment technologies (especially CO2 capture) used in refinery technology are too complex and cost-intensive for the operation of comparatively small biomass plants. The potential for increasing efficiency through suitable integration into the energy system is very high. By coupling gasification with pre-treatment processes such as hydrothermal carbonization, the fuel potential can also be extended to low-melting biogenic residues. The use of straw-like biomass alone in DFB gasification could lead to an increase in SNG production of around 11 TWh/a in Austria - other input materials are possible. Through suitable sector coupling with the energy system using e.g. electrolysis H2, the carbon utilization rate can be roughly doubled compared to the current state of the art. The SNG product generation costs can be significantly reduced with the proposed solutions and, according to the current state of knowledge, are then less than half of the penalty payments as mentioned in the Renewable Gas Act (EGG) of €150/MWh. |

Project Manager

Florian Benedikt, Ass.Prof. Dipl.-Ing.Dr.

- florian.benedikt@boku.ac.at

- Phone

- +43 1 47654-89313

- Postal address

-

Chemical and Energy Engineering

Muthgasse 107/I (Muthgasse 107)

1190 Vienna

Additional links

Partners of the research consortium

Acknowledgements

This project is funded by the Climate and Energy Fund and carried out as part of the 2023 Energy Research Program.