HVAC optimization

HVAC optimization

Technical and organizational measures have already been taken at several sites concerning multiple institutional buildings of the University.

As already well-known from practical studies and investigations, internal energy analyses of the building stock of the University have also shown, that ventilation (Air Handling Units) and cooling (Chillers) are the most energy intensive technical building services.

In the case of AHUs, time control is a simple yet very effective method to reduce energy consumption, leading to multiple energy savings in electrical as well as thermal energy. Load reduction/adaptation during periods with low demand (e.g. nighttime, weekend etc.) is therefore being implemented in the building automation and control system (BACS) of each building complex. Furthermore, the transition towards flexible temperature and humidity control in low demand periods leads to additional savings.

The following measures have either been already realized or are planned to be applied on the below listed university buildings in the near future: 1. Facilities in Tulln/ University and Research Campus Tulln

- Detailed assessment of demand and air comfort through user surveys based on individual interviews and discussions

- Adaptation of AHU-control in BACS (integration of multiple stage operation)

2. Facilities in Muthgasse/ Emil Perels Building, Armin Szilvinyi Building, Simon Zeisel Building

- Detailed assessment of demand and air comfort through user surveys based on individual interviews and discussions

- Adaptation of AHU-control in BACS (integration of multiple stage operation)

- Installation of an energy monitoring system for continuous measuring of energy consumption as well as control and evaluation/optimization of the building’s operation

- Demand controlled optimization of the heating and cooling system in BACS; Adaptation of set values and transitional control curves for temperature and humidity

- Optimization of the emergency power unit through ambient supply and discharge of cooling air

- Optimization of process control of the cooling system and adaptation of district cooling power based on performed analyses of the cooling demand in summer

- Conversion of domestic hot water supply from centralized DH-system to (partly) electrical flow heaters; cost-effective reduction of hydraulic system losses

- Exchange (LED) of illuminants in energy-intensive laboratories; reduction of cooling demand in cooling chambers

So far, the energy-costs-savings potential adds up to approximately 140.000,- Eur per year.

Practical example - cooling supply (Chillers):

Due to high requirements on indoor air quality, cooling/refrigeration is essential for running a high-performance research- and teaching institution. Besides peak cooling loads for air ventilation in summer, continuous cooling demand for specific technical equipment has to be satisfied: Cooling chambers, electrical transformers, compressors and some laboratory equipment need to be cooled during the whole year.

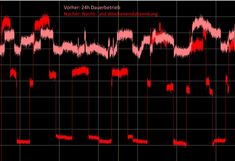

Data analyses have shown, that the old chillers at BOKU operate in a very inefficient way and constantly at high loads. Focus herein lies on the analysis of the overall operational behavior and on optimization of the process control to improve energy efficiency. Besides the optimization of the control strategies, there is explicit need to modernize the cooling system because of the age of certain components (compressors, pressure valves, pumps etc.)

contact: jan.kotik@boku.ac.at