Lightweight Concrete Structures

According to reports by the International Energy Agency, reinforced concrete is the most widely used building material worldwide. In this context, the production of cement—an indispensable component of conventional concrete—accounts for more than 4% of global anthropogenic carbon dioxide emissions. Research into new material compositions, structural concepts, and manufacturing technologies that reduce environmental impact is therefore one of the most pressing tasks in today’s construction research.

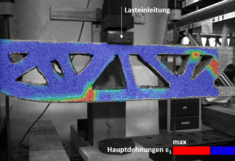

One approach pursued by IGCE is the structural optimization of concrete components. By reducing material that does not contribute to load-bearing capacity, ecological efficiency can be increased. Currently, various geometrical configurations are being investigated both numerically and experimentally.

In addition to structural optimization, the research group also explores the potential of high-performance materials. Beyond non-metallic reinforcement (carbon fiber reinforced polymers CFRP, glass fiber reinforced polymers GFRP, and basalt fiber reinforced polymers BFRP – in textile or bar form), several high-performance concretes are being studied, including high-strength concrete (HPC), ultra-high-performance concrete (UHPC), and ultra-high-performance fiber-reinforced concrete (UHPFRC), each with the goal of minimizing the ecological footprint of construction.

The realization of optimized concrete components—often characterized by geometrically complex, even organic-looking structures—requires parallel research into suitable manufacturing methods and connection technologies.The research group is investigating various approaches, such as 3D printing with concrete, the use of 3D-printed formwork, and conventional casting methods for comparison. In the long term, the aim is to develop robot-assisted processes for automated reinforcement placement, formwork, and casting, enabling greater process stability and improved performance. See also the project AUTOMCONCRETE.

IGCE is also actively contributing to the establishment of new material combinations of non-metallic reinforcement and concrete within the framework of the project SusDeCon – Sustainable Design and Construction with Non-Metallic Reinforcement In this broad consortium of universities, designers, reinforcement manufacturers, and contractors, fundamental work is being carried out to advance the practical applicability of non-metallic reinforcement in construction.

Keywords: Carbon reinforcement, CFRP, UHPC, innovative construction materials, lightweight concrete

Contact:

News:

Publications:

2025

Pressmair N., Hammerl M., Reichenbach S., Kromoser B.: Evolution of material-efficient concrete girders: Conceptual design informed by topology optimisation and experimental testing regime DOI: 10.1016/j.engstruct.2024.119535

2024

Hammerl M., Reichenbach S., Pressmair N., Kromoser B.: Short‐length mechanical bond anchorage for reinforcement bars made of FRP: Experimental and numerical investigations DOI: 10.1002/suco.202400066

2023

Hammerl M., Reichenbach S., Kromoser B.,Thin-Walled Slab Elements Made of FRP-Reinforced HPC and UHPC: Development, Experimental Investigation and LCA DOI: Symposium 2023. 2023.

2022

Hammerl M., Kromoser B.: Filigree Slab Elements made of Carbon reinforced HPC - Development, Production and Experiments DOI: September 2022

Hammerl M., Kromoser B.: Bending failure mechanisms of non-prestressed and prestressed thin-walled uhpc beams reinforced with CFRP DOI: Proceedings fib Congress 2022 Oslo

Pressmair N, Brosch F, Hammerl M, Kromoser B. Non-linear material modelling strategy for conventional and high-performance concrete assisted by testing DOI: 10.1016/j.cemconres.2022.106933

Hammerl, M; Kromoser, B Bending Behaviour of Prestressed T-Shaped Concrete Beams Reinforced with FRP-Experimental and Analytical Investigations. DOI :10.3390/ma15113843

Preinstorfer, P; Huber, T; Reichenbach, S; Lees, JM; Kromoser, B Parametric Design Studies of Mass-Related Global Warming Potential and Construction Costs of FRP-Reinforced Concrete Infrastructure.DOI :10.3390/ma15113843

Brosch, F; Stoiber, N; Hammerl, M; Kromoser, B (2022): NUMERICAL MODELLING STRATEGY FOR UHPC STRUCTURES: MODEL CALIBRATION ASSISTED BY TESTING AND APPLICATION ON A HIGH-PERFORMANCE BEAM.

[fib Congress 2022 Oslo, Oslo, NORWAY, 13.06.2022 - 16.06.2022]

Reichenbach, S; Stoiber, N; Kromoser, B (2022): Cradle-to-gate LCA of FRP reinforcement for concrete structures.

[fib Congress 2022 Oslo - Concrete Innovation for Sustainability, Oslo, NORWAY, 13.06.2022 - 16.06.2022]

Stoiber, N; Hammerl, M; Kromoser, B (2022): Environmental Assessment of Non-metallic Reinforcement for Concrete Structures as an Alternative to Steel Reinforcement . DOI: Vol. 33 (2022):

2021

Stoiber, N.; Kromoser, B: Topology optimization in concrete construction: a systematic review on numerical and experimental investigations. 2021, Structural and Multidisciplinary Optimization. 64: 1725-1749. DOI: https://doi.org/10.1007/s00158-021-03019-6

Stoiber, N.; Kromoser, B. (2021): Pushing concrete material usage to the limit: Weight optimized, 3D printed concrete girders with external reinforcement. [International fib Symposium – Conceptual Design of Structures 2021, Switzerland, 16. – 18. September 2021]

Hammerl, M; Kromoser, B The influence of pretensioning on the load-bearing behaviour of concrete beams reinforced with carbon fibre reinforced polymers. DOI:10.1007/s00158-021-03019-6

Preinstorfer, P; Huber, P; Huber, T; Kromoser, B; Kollegger, J Experimental investigation and analytical modelling of shear strength of thin walled textile-reinforced UHPC beams.DOI: https://forschung.boku.ac.at/de/publications/136265

Reichenbach, S; Preinstorfer, P; Hammerl, M; Kromoser, B A review on embedded fibre-reinforced polymer reinforcement in structural concrete in Europe. DOI:Construction and Building Materials. 2021;307.

Hammerl, M; Kromoser, B (2021): Load-bearing Behaviour of Pretensioned Thin-walled Concrete Structures Reinforced with CFRP.

Preinstorfer, P; Reichenbach, S; Huber, T; Kromoser, B (2021): Potential Fields of Application for CFRP Reinforcement in Concrete Infrastructure Engineering: Material Availability, Application Areas and Static Parametric Study with Consideration of the GWP.

Reichenbach, S; Kromoser, B; Preinstorfer, P; Huber, T (2021): Application potential of textile reinforcement in concrete construction for infrastructure buildings: Environmental performance and availability.

Kromoser, B.: (2021): Ressourceneffizientes Bauen mit Betonfertigteilen. Material - Struktur - Herstellung.

Preinstorfer, P; Kromoser, B Influence of geometrical parameters on the splitting forces in textile-reinforced concrete. DOI: Materials and Structures. 2020;53(6).

Suppanz, F; Kromoser, B Bond behavior of subtractive machined CFRP rods in UHPC. DOI: Beton- und Stahlbetonbau. 2020;115(7):504-+.

2020

Hammerl, M; Kromoser, B (2020): Prestressing of carbon fiber reinforced concrete.

Kromoser, B; Preinstorfer, P; Kollegger, J Building lightweight structures with carbon-fiber-reinforced polymer-reinforced ultra-high-performance concrete: Research approach, construction materials, and conceptual design of three building components. DOI: Structural Concrete. 2019;20(2):730-44.

Preinstorfer, P; Kromoser, B; Kollegger, J Categorisation of the bond behaviour of textile reinforced concrete. DOI: Bauingenieur. 2019;94(11):416-24.

Preinstorfer, P; Kromoser, B; Kollegger, J Flexural behaviour of filigree slab elements made of carbon reinforced UHPC. DOI: Construction and Building Materials. 2019;199:416-23.

2019

Kromoser, B (2019): Thin walled CFRP reinforced UHPC structures – towards efficiency in concrete engineering?.

2018 Originalbeitrag in Fachzeitschrift

Kromoser, B; Kollegger, J Conceptual design, geometry optimization and calculation of the concrete shell bridge AM2 built with PFHC. DOI: Beton- und Stahlbetonbau. 2018;113(2):88-95.

Kromoser, B; Kollegger, J; Kari, H; Gradenegger, K; Ganster, M Practical Application of an innovative concrete shell construction method: Construction of the deer pass AM2 by use of PFHC. DOI: Beton- und Stahlbetonbau. 2018;113(3):222-3.

Publizierter Beitrag für wissenschaftliche Veranstaltung

Kollegger, J.; Kromoser, B.; Suza, D.: (2018): Erection of bridges and shells without formwork - challenges for the computational modelling. [Conference on Computational Modelling of Concrete and Concrete Structures (Euro-C), Bad Hofgastein, 26. February - 1 March 2018] In: Meschke, G.; Pichler, B.; Rots J.G. (Eds.), Computational Modelling of Concrete Structures ; ISBN: 978-1-138-74117-1

2017 Originalbeitrag in Fachzeitschrift

Kromoser, B; Kollegger, J Active Shaping of hardened Concrete Elements for the Production of spatially crushed Concrete Surfaces. DOI: Beton- und Stahlbetonbau. 2017;112(2):106-15

Kromoser, B.; Kollegger, J.: (2017): Construction of a thin walled concrete shell event canopy. [CCC Tokaj, Tokaj, 31.08. - 1.09.2017]

Kromoser, B.; Kollegger, J.: (2017): How to inflate a hardened concrete shell with a weight of 80 t. [IASS Annual Symposium 2017 , Hamburg, 25. - 28. September 2017]

Preinstorfer, P.; Kromoser, B.; Kollegger, J.: (2017): Dünnwandige Bauteile aus carbonbewehrtem Ultrahochleistungsbeton . [VÖZ Kolloquium 2017, Wien, 13.11.2017]

Preinstorfer, P.; Kromoser, B.,;Kollegger, J.: (2017): Development of prestressed T-beams made of textile reinforced UHPC. [39th IABSE Symposium, Vancouver, 19. - 23. September 2017]

2016 Originalbeitrag in Fachzeitschrift

Hawkins W., Herrmann M., Ibell T., Kromoser B., Michaelski A., Orr J., Pedreschi R., Pronk A., Schipper R., Shepherd P., Veenendaal D., Wansdronk R., West M.: Flexible formwork technologies - a state of the art review. DOI: Structural Concrete. 2016;17(6):911-35.

Kromoser B., Huber P.: Pneumatic Formwork Systems in Structural Engineering. DOI: Advances in Materials Science and Engineering. 2016

Kromoser B, Ritt M.: Optimized shapes for textile reinforced concrete structures - design of the barbecue furniture "Donauwelle". DOI: Bauingenieur. 2016;91:425-33.

Publizierter Beitrag für wissenschaftliche Veranstaltung

Kromoser B., Kollegger J., Pachner,T.: (2016): Building concrete shells without formwork and falsework. [fib Symposium 2016 , Cape Town, 21. - 23. November 2016]

Kromoser B., Kollegger J.: (2016): Structural Optimization of a concrete shell bridge with the Pneumatic Forming of Hardened Concrete construction method. [IASS 2016 International Symposium, Tokyo, 26.9. - 30.9.2016]

Preinstorfer P., Kromoser B., Kollegger J.: (2016): On the Bond Behaviour between Double-Wall Elements made of HPC/UHPC and ordinary cast-in-situ Concrete.

[HIPERMAT 2016, Kassel, 9.3. - 11.3.2016]

2015 Originalbeitrag in Fachzeitschrift

Kromoser B; Kollegger J Pneumatic forming of hardened concrete - building shells in the 21st century. DOI: Structural Concrete. 2015;16(2):161-7.

Kromoser B.; Kollegger J.: (2015): Application Areas for Pneumatic Forming of Hardened Concrete. Journal of the IASS, 56, 187-198; ISSN 1028-365X

Publizierter Beitrag für wissenschaftliche Veranstaltung

Kollegger J.; Kromoser B.: (2015): Neue Tragwerke – Eine Betonkuppel zum Aufblasen.

[59. Betontage Ulm, Ulm, 24. - 26.2.2015]

Kromoser B.: (2015): Thin-walled textile concrete furniture. [The 11th Central European Concress on Concrete Engineering, Hainburg, 1.10. - 2.10.2015]

Kromoser B.; Kollegger J.: (2015): Building shells from initially flat hardened concrete plates.

[IASS 2015, Amsterdam , 17.8. - 20.8.2015]

Dissertation

Kromoser B.: (2015): Pneumatisches Verformen Von Ausgehärtetem Beton - Die Errichtung Von Betonschalen Aus Ursprünglich Ebenen Platten. ; TU Wien, Institut für Tragkonstruktionen - Forschungsbereich für Stahlbeton und Massivbau

2014 Originalbeitrag in Fachzeitschrift

Kromoser B., Kollegger J,; Manufacturing of shell structures made of concrete with the "Pneumatic Wedge Method" A new Construction Method for the Construction of Double-Curved Concrete Surface by using Pneumatic Formwork. DOI: Beton- und Stahlbetonbau. 2014;109(8):557-65

Kromoser B., Kollegger J.: (2014): Building free formed concrete surfaces by using the “pneumatic wedge method. [The 10th fib International PhD Symposium in Civil Engineering , Quebec, 21.7. - 23.7.2014] ; ISBN: 978-2-9806762-1-5