AUTOMCONCRETE

Productivity and material efficiency in the construction industry remain comparatively low compared to other sectors. In addition, the shortage of skilled labor in the building trades is steadily increasing. To counter these challenges, a stronger automation process in planning and construction is essential. A key prerequisite for this is the implementation of repeatable processes in design and production. However, such processes often lead to monotonous building structures, reminiscent of the mass-produced architecture of the 1970s.

In contrast, today’s high-quality building culture is characterized by individuality, which at first glance seems to conflict with automation. To create a solid basis for the development of modular building systems that can be automatically optimized and manufactured, it is crucial to evaluate the needs and requirements regarding the desired level of individuality. At the institute, we are therefore conducting fundamental research to better understand this tension. In addition, we are developing automated design and optimization strategies for concrete components such as beams and slabs, with a particular focus on simplifying and generalizing these strategies to achieve real efficiency gains. Our ultimate goal is to provide the construction industry with modular, adaptable, and resource-efficient structural elements that can be designed and produced through automated processes.

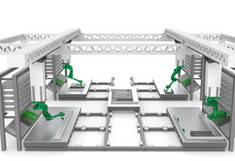

In parallel, we are investigating the possible automation of manufacturing processes. Current automated techniques—such as those used in the precast industry for double wall production—offer only limited flexibility. By contrast, the use of multiple 6-axis industrial robots promises significant productivity gains. Central to this research are automated formwork systems for structurally optimized slab and beam constructions, as well as strategies enabling simple and ultimately automatic geometry changes.

AutomConcrete I

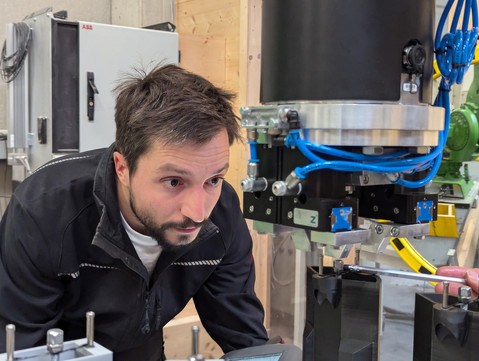

The first project, AutomConcrete I, focused on developing fundamental methods and technologies for automated concrete construction. This included initial concepts for automated formwork systems, the development of material models, and digital strategies for structurally optimized component design. In laboratory environments, prototypes were tested, demonstrating the feasibility of robot-assisted construction.

AutomConcrete II

Building on these results, the follow-up project AutomConcrete II transfers the developed approaches into more practice-oriented applications. While the first phase concentrated on basic principles, the current focus is on scaling up the models and demonstrating their applicability to full-scale building components.

One emphasis lies on investigating the placement accuracy of formwork systems, which is being experimentally validated. Complementary to this, 3D laser scanning technologies are applied to ensure precise measurement and continuous quality control of the components. In parallel, a digital simulation environment is being developed to test different prototypes, robotic scenarios, and placement strategies, further increasing efficiency before implementation in real experiments.

Moreover, structurally optimized beams are being modeled and manufactured. Accompanying tests are used to verify and validate the material model developed in the project, ensuring a successful transfer of theoretical approaches into practice. By introducing simple, repeatable voids inspired by famous truss configurations into the RC beams, the approach achieves up to 20% savings in concrete and corresponding reductions in CO₂ emissions, without relying on costly high-performance materials.

With AutomConcrete II, a decisive step is being taken towards an integrated robotic construction process that not only increases efficiency and precision, but also ensures quality and variability in modern concrete construction.

Partner:

- Holcim AG

- Umdasch Group Ventures GmbH

- Kirchdorfer Industries GmbH

Contact:

News:

Publications:

- Kromoser B., Ahmed I,. Reichenbach S., Development of a simplified strategy for topology optimisation of reinforced concrete beams using regular geometric shapes, in DOI: Lecture Notes in Civil Engineering*, Springer, Jun. 2023, pp. 1–12. [Online]. Available

- Kromoser B., Ahmed I,. Reichenbach S., Flexural behaviour of reinforced concrete beams with voids: Topology optimisation basis, DOI: 10.1016/j.istruc.2024.107037

- Kromoser B, Gappmaier P, Ahmed I, Reichenbach S. Circular economy in concrete construction through modular construction, automated design and production of structurally optimised reusable concrete building components. Case Studies in Construction Materials 2025;23:e05139. DOI: 10.1016/j.cscm.2025.e05139

- Reichenbach, S., Kromser, B. State of Practice of Automation in Precast Concrete Production. Journal of Building Engineering. Nov 2021. DOI: 10.1016/j.jobe.2021.102527

- Stoiber, N; Kromoser, B Topology optimization in concrete construction: a systematic review on numerical and experimental investigations. STRUCT MULTIDISCIP O. 2021; 64(4): 1725-1749 DOI: 10.1007/s00158-021-03019-6

- Stoiber, N; Kromoser, B (2021): Pushing concrete material usage to the limit: Weight optimised, 3D printed concrete girders with external reinforcement.[ International fib Symposium - Conceptual Design of Structures 2021, Solothurn, SWITZERLAND, SEP 16-18, 2021] In: FIVET, C; D'ACUNTO, P; FERNANDEZ RUIZ, M; OHLBROCK, P (Eds.), Proceedings of the International fib Symposium on the Conceptual Design od Structures ; ISBN: 978-2-940643-12-7 actu.epfl.ch/public/upload/files/fulltext.pdf

- Gappmaier P, Reichenbach S, Kromoser B. Automated Production Process for Structure-Optimised Concrete Elements. In: Springer Nature , editor. Building for the Future: Durable, Sustainable, Resilient Proceedings of the fib Symposium [Internet]. 2023. DOI: 10.1007/978-3-031-32511-3_161

- Gappmaier P, Reichenbach S, Kromoser B. Advances in formwork automation, structure and materials in concrete construction. Automation in Construction. 2024;162:105373. DOI: 10.1016/j.autcon.2024.105373

- Kromoser B, Gappmaier P, Ahmed I, Reichenbach S. A New Approach for Automated Design and Robot-Assisted Production of Structurally Optimised Reusable Concrete Building Elements. In: Lowke D, Freund N, Böhler D, Herding F , editors. Digital Concrete 2024 - Supplementary Proceedings. Universitätsbibliothek Braunschweig; 2024. DOI: 10.24355/dbbs.084-202408141320-0

- Gappmaier P, Reichenbach S, Kromoser B. Fertigungsprozess für topologieoptimierte Betonfertigteile mit innovativen Schalungen. In: Schlicke D, Krüger M, Freytag B, Laggner T , Herausgeber. 6. Grazer Betonkolloquium. Technische Universität Graz; 2024 DOI: 10.3217/978-3-99161-015-1

- Reichenbach S, Gappmaier P, Kromoser B. Decreasing environmental and increasing economic impact within the prefabricated industry – Automated design and production of structurally optimised concrete components. 20th fib Symposium Proceedings in Christchurch. ReConStruct: Resilient Concrete Structures. International Federation for Structural Concrete; 2024. https://shop.fib-international.org/publications/fib-proceedings/1006-20th-fib-symposium-proceedings-in-christchurch-2024-new-zealand-pdf

- Gappmaier P, Reichenbach S, Kromoser B. Integration of industrial robots for sustainable and efficient production of concrete elements with advanced formwork towards industry 4.0. 20th fib Symposium Proceedings in Christchurch. ReConStruct: Resilient Concrete Structures. International Federation for Structural Concrete; 2024. https://shop.fib-international.org/publications/fib-proceedings/1006-20th-fib-symposium-proceedings-in-christchurch-2024-new-zealand-pdf