Advanced lignin characterization

SUPERVISOR: Antje POTTHAST

PROJECT ASSIGNED TO: Margaritha RITSCHER

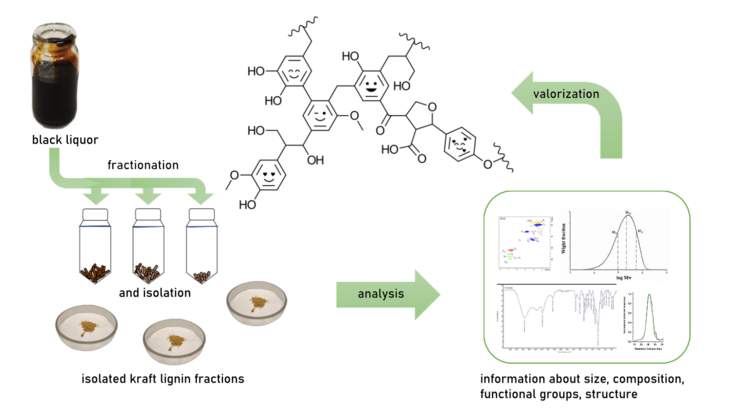

The kraft process is the dominant pulping process in the pulp and paper industry today, accounting for the production of 90 % of chemical pulp worldwide. In this process, most of the lignin is extracted from the wood by breaking it chemically down and dissolving it in the cooking liquor which is then referred to as black liquor.

The resulting technical lignin, referred to as kraft lignin, is a by-product of the pulping process and differs drastically from the lignin in its native form. New structures are formed due to condensation while native structures are degraded, which affects molecular properties such as molar mass, the content and type of functional groups and bonding pattern. As a result of the harsh conditions during pulping, kraft lignins show a significant loss in reactivity and solubility. However, kraft lignins remain to be the potential main source for technical lignin due to their large production scale.

For their valorization, it is crucial to understand their structure and associated properties. In this project the goal is to obtain a better understanding of the behavior of kraft lignin to optimize its fractionation to unlock its value.