Bioleaching of critical metals from spent Lithium-ion batteries

SUPERVISOR: Georg GÜBITZ

PROJECT ASSIGNED TO: Lalropuia LALROPUIA

The demand for Lithium-ion batteries (LIB) dramatically increases in recent years due to its application in different electronic devices but mainly due to its use in electric vehicles (EVs) and is projected to further increase in the near future[1]. This results in generation of large amounts of LIB wastes most of which will end up on landfills, posing potential environmental threats and may further lead to insufficient supply of the required raw materials for Li-batteries production like Co, Ni, Li etc. [2]. The LIB wastes contain substantial amounts of critical metals and can therefore act as a good secondary source for these metals. Additionally, efficient recycling of LIB could help to mitigate the environmental impacts as well as reduce the mining of virgin minerals [3]. In this thesis, recovery of critical metals such as Li, Co, Ni, Mn, Cu, etc. from the black mass of spent LIB will be investigated using bioleaching, a process which uses microorganisms to solubilized metals mainly from sulphidic ores but also from other secondary sources such as LIB, ashes and slags, etc.[4] Bioleaching is a viable option due to its economic advantage and environmental friendliness as compared to the conventional method of recycling which is mainly done by pyro or hydrometallurgical processes [5]. During this study, a screening for suitable microorganism will be performed and bioleaching of the black mass (BM) from spent LIB will be tested using two approaches i.e. direct and indirect leaching. At the end, the aim is to achieve high leaching efficiencies of critical metals under optimal conditions such as pH, pulp density, temperature, etc. and potentially upscaling the optimized bioleaching process.

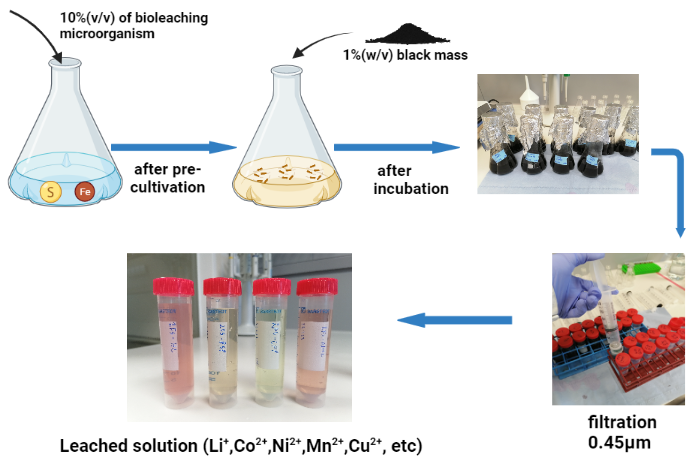

Figure 1: Experimental steps for direct leaching of black mass

Reference

[1] T.-H. Kim, J.-S. Park, S. K. Chang, S. Choi, J. H. Ryu, and H.-K. Song, “The Current Move of Lithium Ion Batteries Towards the Next Phase,” Adv. Energy Mater., vol. 2, no. 7, pp. 860–872, 2012, doi: doi.org/10.1002/aenm.201200028.

[2] O. E. Bankole, C. Gong, and L. Lei, “Battery Recycling Technologies: Recycling Waste Lithium Ion Batteries with the Impact on the Environment In-View,” J. Environ. Ecol., vol. 4, no. 1, p. 14, Jun. 2013, doi: 10.5296/jee.v4i1.3257.

[3] A. Boyden, V. K. Soo, and M. Doolan, “The Environmental Impacts of Recycling Portable Lithium-Ion Batteries,” in Procedia CIRP, 2016, vol. 48, pp. 188–193. doi: 10.1016/j.procir.2016.03.100.

[4] K. Kremser et al., “Leachability of metals from waste incineration residues by iron- and sulfur-oxidizing bacteria,” J. Environ. Manage., vol. 280, p. 111734, 2021, doi: 10.1016/j.jenvman.2020.111734.

[5] W. Krebs, C. Brombacher, P. P. Bosshard, R. Bachofen, and H. Brandl, “Microbial recovery of metals from solids,” FEMS Microbiol. Rev., vol. 20, no. 3, pp. 605–617, 1997, doi: doi.org/10.1016/S0168-6445(97)00037-5.