Fastening systems play an important role in current and especially future construction work. The requirements of the future – faster and automatized construction, preservation of our cultural heritage and historic buildings, improved performance and sustainability of infrastructure, among others – can only be met with a deeper understanding regarding the load carrying mechanisms of various fastening systems, as well as the consequences of ageing, environmental influences and extreme events.

The ability to realistically assess and predict the life-time performance of anchors is paramount for the development of fastening technology in the 21st century. The accurate assessment of existing systems provides the means for optimized maintenance planning, rehabilitation, and renovation. On the other side, life-cycle performance based design of fastening systems guarantees cost-efficient, sustainable, and safe future infrastructure. Life-cycle robustness expands this concept to also include unforeseen events during installation, service life, and demolition.

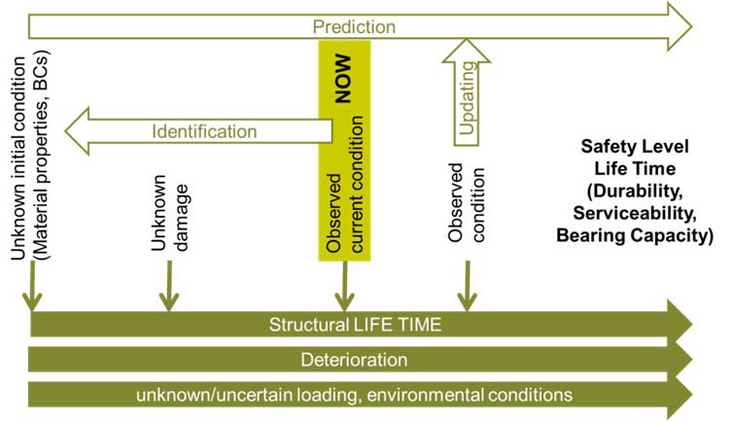

Life-cycle robustness in the sense of this research is defined as the ability of a component or system to maintain its intended function and required safety level, in spite of damage, ageing, extreme events, or changes in usage throughout all phases of an anchor’s life-cycle. Life-cycle robustness comprises the aspects of installation robustness during the construction phase, structural life-time robustness during the operational phase, but also aspects of the demolition and recycling phase.

Over the years a significant amount of research has been performed, mostly focused on the mechanics of single systems, certain degradation mechanisms or material properties. However, there is still much left to investigate in the interaction between components in time, considering ageing materials, deterioration mechanisms and extreme events. A better understanding of prediction uncertainty, stochastic models for input variables and their statistical dependence finally unlocks the potential for cost-efficient and safe future infrastructure.

The research project LIFE CYCLE ROBUSTNESS IN FASTENING TECHNOLOGY represents a comprehensive approach to the investigation of the fundamental mechanisms influencing the life-cycle robustness and life time performance of fastening systems. The output not only enables the assessment of existing fastening systems with regard to their remaining service life but also provides the basis for the optimized development of new products and technologies. In particular, ‘virtual testing’ will significantly accelerate product development and reduce costs, as tests can be limited to the experimental verification of numerically optimized systems.

A ‘life-cycle fastening simulator’ furthermore allows the virtual investigation of different possible life-cycle scenarios. Thus, future demands of the market can be anticipated before the evidence of a certain development can be observed. Finally, the project will yield the basis for performance based design concepts in fastening technology and transparent safety levels.