In general, even a sophisticated model embedded within the most advanced simulation framework will not be able to exactly capture the real behavior of any engineering structure – with and without fastening systems – due to aleatory and epistemic uncertainties and limited knowledge. However, a properly calibrated model should be able to provide a good estimate. The amount of deviation that has to be expected is dependent on both the scatter in the applied loads as well as the amount of uncertainty in the mechanical properties of the used materials (due to inherent heterogeneities). Further uncertainties arise from geometrical tolerances and variations in the installation procedure [150, 151]. If the time dimension is added to the problem (as required for any life time prediction) the uncertainty associated with the predicted mean response increases significantly with the time span of extrapolation, in particular if degradation processes and extreme events are to be considered.

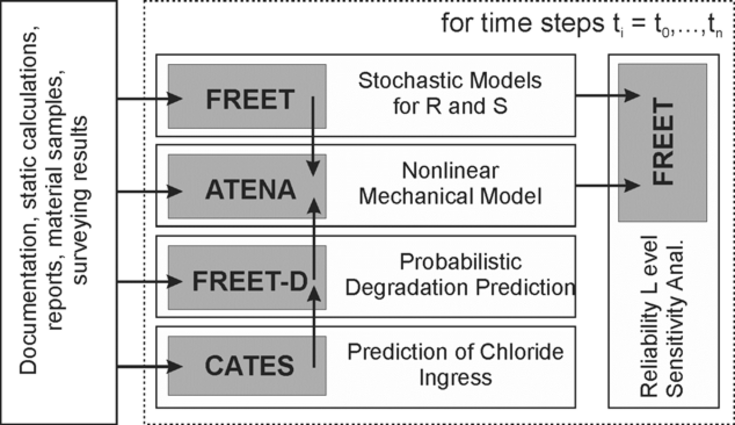

Important processes influencing the long term performance of concrete structures connected or equipped with fastenings are apart from loads (which might change over time e.g. due to changes in usage) and environmental impacts causing e.g. corrosion, the time dependent processes creep, shrinkage [152] and relaxation. Furthermore deterioration processes associated with the corrosion of reinforcement, e.g. due to carbonation or chloride ingress, [153, 154] as well as fatigue phenomena in concrete and steel influence the life-cycle performance. Meaningful life-cycle management of infrastructure is solely possible through the integration of stochastic degradation prognosis approaches [155] which have to include appropriate monitoring concepts, as proposed in [156] for steel corrosion.

Ultimately, accurate prognosis models will allow for an optimized design of new fastening systems but also an accurate assessment of existing systems and thus facilitate efficient maintenance management over the full life time.

In order to meet/ensure the safety requirements that are set by society a deepened understanding, not only of mechanisms on a deterministic level, but especially of stochastic processes is required. These safety requirements are defined in EN 1990 [31] with a failure probability of 10-6 per year for the ultimate limit state and 10-3 per year for the serviceability limit state.

The research work in WP3 will rely heavily on literature studies. Through a thorough review of published stochastic models and correlation investigations, a comprehensive database for the use within the framework for the life-cycle performance assessment of fastening systems will be established. In particular, the statistical properties of relevant loads, material properties, and the uncertainty associated with deterioration prediction models will be compiled. Prof. Novák, CTU in Brno, who is specialized on stochastic mechanics and with whom a long-term collaboration exists, will contribute his expertise as external consultant.

Due to the long history of the Institute of Structural Engineering in testing anchors, a quite profound set of data already exists, that will support the intended research work. Similarly, the industrial partners Hilti and fischerwerke have significant data material to contribute.

This literature review and collection of already existing data will be complemented by extensive experimental investigations to supplement missing information and characterize new or not fully investigated materials. In particular, correlation information, e.g. in form of copula functions, will be derived and experimentally validated.

Life-cycle robustness analysis of fastening systems also encompasses a comprehensive understanding of loads and associated uncertainties. Respective models will be collected through literature review and stored in form of a load model database.