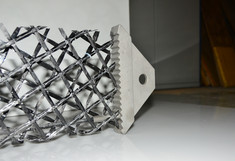

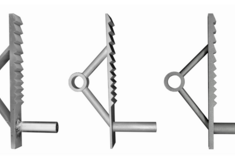

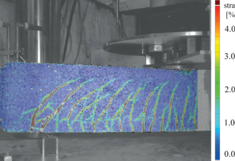

New building materials like carbon reinforcement and ultra-high performance concrete exhibit a high potential to build very thin-walled building components, but they require new production and connection technologies. For example, introducing high loads into the thin structural members leads to local peak stresses. Steel implants, designed by use of structural and topological optimization in collaboration with Professor Werner Sobek, who leads the Institute for Lightweight Structures and Conceptual Design (ILEK) at the University of Stuttgart, can reduce these stresses and increase the utilization factor of the materials. In addition, a simplification of the connection technology of the concrete elements goes along with the use of these implants.

In general, structurally optimized building components produce very resource efficient and geometrically complex structures. Within our research, we investigate the use of new production technologies like 3D printing to simplify their manufacturing.

Keywords: Innovative connection technology

Contact:

Partner:

Publications:

** Kromoser, B; Gericke, O; Hammerl, M; Sobek, W Second-Generation Implants for Load Introduction into Thin-Walled CFRP-Reinforced UHPC Beams: Implant Optimisation and Investigations of Production Technologies.

** Kromoser, B; Strieder, E; Kirnbauer, J Self post-tensioning ultra-high performance concrete elements The activation of with iron based shape memory alloys reinforced UHPC elements by thermal follow up treatment.

2017 Article in conference proceedings

Preinstorfer, P.; Kromoser, B.; Kollegger, J.: (2017): Dünnwandige Bauteile aus carbonbewehrtem Ultrahochleistungsbeton .

[VÖZ Kolloquium 2017, Wien, 13.11.2017]

Preinstorfer, P.; Kromoser, B.,;Kollegger, J.: (2017): Development of prestressed T-beams made of textile reinforced UHPC.

[39th IABSE Symposium , Vancouver, 19. - 23. September 2017]

2016 Journal article

** Hawkins, W; Herrmann, M; Ibell, T; Kromoser, B; Michaelski, A; Orr, J; Pedreschi, R; Pronk, A; Schipper, R; Shepherd, P; Veenendaal, D; Wansdronk, R; West, M Flexible formwork technologies - a state of the art review.

** Kromoser, B; Ritt, M Optimized shapes for textile reinforced concrete structures - design of the barbecue furniture "Donauwelle". BAUINGENIEUR-GERMANY. 2016; 91: 425-433. WoS

Article in conference proceedings

Preinstorfer, P.; Kromoser, B.; Kollegger, J.: (2016): On the Bond Behaviour between Double-Wall Elements made of HPC/UHPC and ordinary cast-in-situ Concrete .

[HIPERMAT 2016, Kassel, 9.3. - 11.3.2016]

2014 Article in conference proceedings

Kromoser, B.; Eichwalder, B.; Kollegger, J.: (2014): Simulation of large strains in concrete specimen – centric tensile tests using steel ropes as reinforcement.[Euro-C , St. Anton, 24.3. - 27.3.2014] ; ISBN: 978-1-138-00145-9

2012 Article in conference proceedings

Kollegger, J., Kromoser, B., Dallinger, S.: (2012): The building of ice and concrete shells by employing pneumatic formwork. [Second International Conference on Flexible Formwork, Bath, 27.6. - 29.6.2012] In: Orr, J.; Evernden, M.; Darby, A.; Ibell, T. (Eds.), Proceedings of the Second International Conference on Flexible Formwork; ISBN: 978-0-86197-184-8; S

Kromoser, B.; Kollegger, J.: (2012): Using Ice to Build Shell Structures.

[10th International Conference and Exhibition on Performance of Ships and Structures in Ice, Banff, 17.9. - 20.9.2012]