Update: Covid-19 Antibody test

COVID-19 antibody test "Made in Austria" rated excellent in clinical validation!

The corona pandemic has pushed many health care systems and the global economy to their limits. Topics related to the pandemic have become anchored in people's consciousness and everyday life like no other topic in the last 70 years. PCR-based diagnostic methods were developed relatively quickly to investigate acute suspected cases and to prevent the virus from spreading via quarantine measures. However, antibody tests are required to identify individuals who have undergone undetected SARS-CoV-2 infections and to accompany vaccine studies. These tests are more complex to develop compared to PCR-based methods. With the help of these tests, the virus-specific immune response conferred by an infection or vaccination can be examined by measuring the antibodies in the patient (immunological test). Antibody tests are an important tool to assess the effectiveness of vaccine candidates and to derive suitable vaccination modalities. High specificity and sensitivity are of great importance for the quality of an antibody test, since they indicate whether a test can reliably distinguish between healthy and sick individuals. Currently available antibody tests for SARS-CoV-2 have very often produced incorrect or ambiguous results or were out of stock and therefore not suitable for widespread use. An Austrian consortium consisting of three universities - the University of Natural Resources and Applied Life Sciences (BOKU), the University of Veterinary Medicine Vienna (Vetmeduni Vienna) and the Medical University of Vienna (MedUni Vienna) - wanted to remedy this situation. Only four months after their work commenced, the development of the test was successfully completed. A highly specific and sensitive COVID19 antibody test developed in Austria will be available soon!

But first, let's first follow up on our last press releases from 30th March and 10th June. During the last four months, BOKU has been working intensively on the production of several SARS-CoV-2 -derived proteins (antigens) in different biotechnological production systems in order to identify ideal candidates for the serological detection of SARS-CoV-2 antibodies. As previously reported, BOKU originally received genetic material for the production of two coronavirus antigens from the virologist Florian Krammer (Icahn School of Medicine at Mount Sinai, New York). These were for the expression of the SARS-CoV-2 spike protein (S) and the spike receptor binding domain (RBD). The spike protein is a viral membrane protein that forms the characteristic spikes on the virus surface that give the virus its crown (corona)-like appearance. The protein is responsible for the binding of the virus to the host cell and its fusion with the cell membrane. It is therefore crucial for initiating the infection process. A defined region of this protein houses the receptor binding domain, which binds to the angiotensin-converting enzyme 2 (ACE-2), the cellular receptor on the surface of the host cell, and is therefore essential for the infection of the host.

In early April an interdepartmental consortium consisting of scientists from the Departments of Biotechnology (DBT) and Applied Genetics and Cell Biology (DAGZ), the Austrian Centre of Industrial Biotechnology (ACIB) and DBT-associated Spin-Offs (Novasign, enGenes Biotech) was formed at BOKU with the aim of quickly providing these two SARS-CoV-2 antigens for an antibody test. The DBT has a broad expertise and the necessary infrastructure to express (produce) and purify recombinant proteins in different production systems, such as mammalian and insect cells or microbial organisms like bacteria and yeasts, on a small and large scale. The DAGZ extends this expertise by the production of recombinant proteins in plants and the targeted modification of their sugar structures. Scientific curiosity and the need to help drove these teams at BOKU to develop different versions of these antigens, as well as additional antigen candidates and to test them for their suitability for use in an antibody test. BOKU developed a shortened version of the RBD and worked on the production of the viral nucleocapsid protein (NP). This highly immunogenic structural protein is located inside the virus and is required for packaging the viral genome into the virus particles.

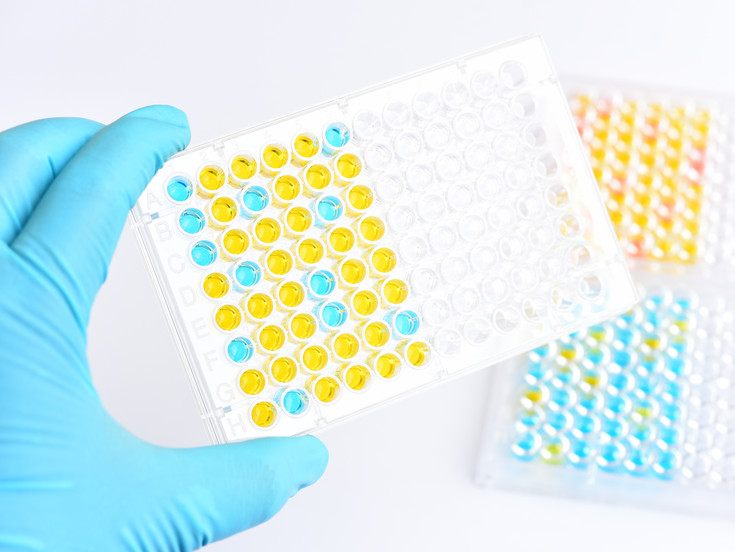

The antigens were produced in a wide variety of production systems available at BOKU. In order to narrow down the wide range of candidates, BOKU worked very closely with the consortium partners, the Institute of Medical Biochemistry and the Institute of Immunology at Vetmeduni Vienna, who subjected all candidates for the antibody test (>30) to an initial pre-validation. At Vetmeduni Vienna the antigens were tested in a 96-well ELISA plate format with a panel on pre-COVID19 sera and selected sera from COVID19 patients with different disease courses provided by MedUni. In addition, all proteins produced were also tested for functionality by the Competence Unit Molecular Diagnostics at AIT Austrian Institute of Technology and the Clinical Department of Nephrology and Dialysis at MedUni Vienna using an alternative test platform. Based on these results, the initial antigen panel was quickly narrowed down. In addition, the first technical optimizations regarding the ELISA setup were made at Vetmeduni Vienna in order to achieve better separation precision between the measured values of samples from infected and non-infected donors. The combination of ELISA performance data, with the available results in terms of product yield, and BOKU's capacity for process scaling led to the decision to use two antigen candidates. In the end, the production of a shortened variant of RBD, the so-called "RBD Shorty", in a human cell line and the production of the nucleocapsid protein in E. coli proved to be optimal for the test.

BOKU and ACIB have established complex purification processes and analytical methods for both processes which guarantee the reproducible production of antigens with a particularly high degree of purity. The high quality of the antigens produced at BOKU has been highly praised by many external partners, as all tests based on these protein reagents are much more precise. The BOKU Core Facilities played an important role in the characterization and qualification of the antigens. With its expertise and infrastructure, the BOKU Core Facility Biomolecular & Cellular Analysis analyzed and verified the functionality of the proteins by establishing binding assays with different molecules (antibodies and receptors) using the Octet system. The BOKU Core Facility Mass Spectrometry analyzed the antigens for their sugar decoration and other modifications, which provided important information to answer relevant questions regarding coronavirus-specific immunity. The excellent cooperation between the participating BOKU departments and institutions allowed for the rapid establishment of complex production processes and the development of sophisticated analytical methods. These ensured the supply of protein reagents of the required quality for use in medical diagnostics. Due to the excellent cooperation of the three universities, BOKU – Vetmeduni Vienna – MedUni Vienna, synergies could be used and complementary expertise could be successfully combined.

In order to ensure a long-term market supply of the developed antibody test, the knowledge that has been gained within the consortium was transferred to two companies and thus exploited in a promising manner. The company enGenes Biotech GmbH, a start-up of BOKU, which had already contributed know-how and technology in the course of production development, has now taken over the production and distribution of the antigens. Technoclone, on the other hand, has perfected the ELISA test developed within the consortium and have further refined the test to allow determination of antibody titers. In addition, Technoclone improved the user-friendliness of the test system and is now providing freeze-dried test plates, which already contain the coupled antigens. On the one hand, this improves the reproducibility of the results while also facilitating the distribution of the tests on the other.

The consortium also wanted to set up the test in such a way that it can be performed by a large number of laboratories, regardless of their size and technical equipment. Now the question arises: "How does this Austrian made antibody test perform?”. To answer this question, the test was subjected to an initial performance evaluation at the Central Laboratory for Medical-Chemical Laboratory Diagnostics at MedUni Vienna. Here, a clinical validation was performed on the basis of 1200 pre-COVID19 sera and over 250 COVID19 patient sera, from donors with weak to severe disease progression, and compared with the results of antibody tests that are already commercially available. In addition, the test was subjected to further stringent testing in the state hospitals (LKHs) of Linz and Innsbruck, where it was evaluated with a total of over 2000 patient sera. Independently of each other, the institutes came to the same conclusion: the antibody test developed in Vienna has an excellent test quality and is suitable for broad clinical application! Since the test does not require dilution robots and shows a very high storage stability, it can be used in very small laboratories in Austria and worldwide.

In order to live/conform to the sustainability and community spirit of BOKU, the produced antigens were also distributed to many other academic and commercial partners for the development of novel test systems and the investigation of COVID19-associated research questions. Not every laboratory has access to recombinant protein production and purification technologies and sophisticated platforms to analyze protein quality. In order to better and more easily coordinate antigen distribution, the BOKU-Startup Novasign GmbH has designed an online platform for BOKU, which will enable BOKU to handle future requests better and faster. Via the BOKU-COVID19 portal, researchers can request test quantities of the proteins produced for COVID19-research and development purposes free of charge (shipping costs only). These are the two SARS CoV-2 antigens developed for the antibody test, RBDshorty and NP, as well as the spike protein. This ensures that BOKU can make an even greater contribution to society in the fight against COVID19. An overview, inquiries and current updates on the currently available antigens are possible at any time after registration.

The biggest challenge in the development of this test was to put together a multidisciplinary team to jointly evaluate the results and draw the right conclusions. Several universities have worked together on this project without ever having been involved in a similar project before. In total, more than 80 people have worked on this project to produce, purify and analyze antigens, develop and perform ELISA tests, test them in a comprehensive way, mediate between different parties and set up contracts. The fact that this development did not originate from a relevant company, where processes of development and commercialization of antibody tests are already established, but from a spontaneously formed collaboration of several universities and companies, underlines the rapid solution competence of the consortium working together here. Within four months, this diverse consortium has managed to bring a COVID19 antibody test "Made in Austria" from an idea to the market. Finally, we would like to thank the Vienna Science and Technology Fund (WWTF) for partially financing the project, ForteBio, a Sartorius Brand, for providing free materials for label-free protein analysis using the Octet system, and the Amazon Web Service for providing free computing capacity using AWS credits for the implementation of the BOKU-COVID19 portal.

For the department, Miriam Klausberger and Mark Dürkop

(09.09.2020)