Synthesis of fully biodegradable core-shell nanoparticles for use in large volume food packaging

SUPERVISOR: Erik REIMHULT

PROJECT ASSIGNED TO: Kuba BOMBA

In Europe 19% of plastic plastic packaging is sent to landfill and 39,5% is sent to incineration. Although mechanical recycling processes are available, they are several difficulties involved, such as downgrading of the mechanical properties, difficulties in processing of multilayer composites, or the presence of potential contaminants.

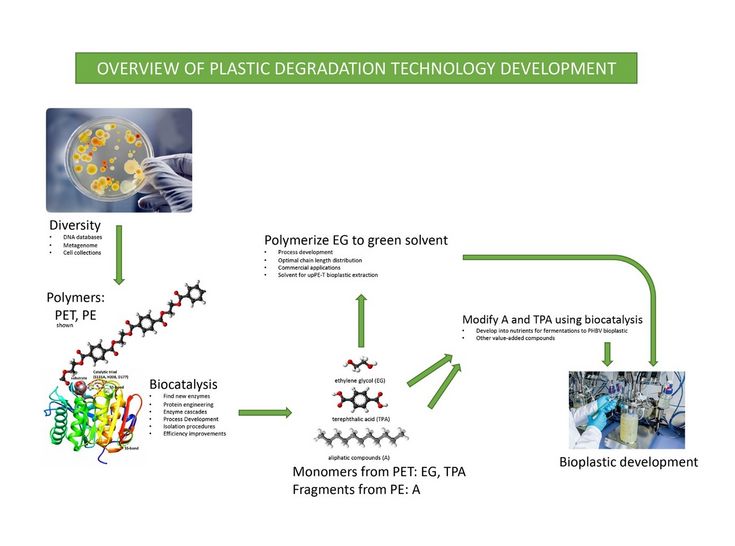

upPE-T project aims to solve it by utilizing enzymatic degradation of polyethylene and poly(etheylene terephtalate) in order to process them into a biomass which in term will be used as a carbon source for bacteria able to produce a variety of biodegradable polymers belonging to the family of polyhydroxyalkanoates. In case of this project, the obtained thermoplastic is a copolymer poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV).

Figure 1 Overview of the upPE-T project (https://uppet.eu/the-project/technology)

PHBV polymers have several highly desirable properties – they are biodegradable and do not downgrade as a result of mechanical recycling process, which makes them a good candidate as a future packaging material. However, they have a a significant downside, namely their poor mechanical properties in comparison to typical packaging thermoplastics.

This doctoral project aims to solve that issue by synthesizing core-shell nanoparticles with inorganic core and biodegradable polymeric shell. Such nanoparticles can be used as a filler material for PHBV thermoplatics and improve their mechanical properties to the point which would make them able to compete with classical packaging materials such as polyethylene, polypropylene and poly(ethylene terephtalate).

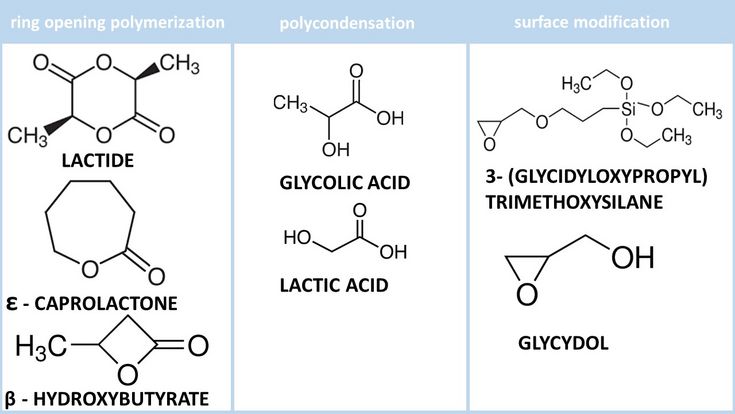

The aim of the project is to produce nanoparticles with different grafting densities and polymer chain-lenghts and test how the mechanical properties of the final PHBV-core-shell nanocomposite are affected. Different monomers and polymerization techniques will be used – polycondensation in order to graft poly(lactic acid), poly(glycolic acid) and poly(butylene terephtalate-co-butylene adipate), and ring opening polymerization in order to graft poly(lactide), poly(ε-caprolactone) and polyhydroxybutyrate.

Figure 2 Grafting and surface modification of nanoparticles