AUTOMCONCRETE II: From Digital Models to Real Beams

Project Update from AutomConcrete II – our mission to digitize and automate the production of structurally optimized precast concrete elements is in full swing!

Funded by Umdasch Group Ventures, Holcim Ltd., and Kirchdorfer Concrete Solutions, our PhD candidate Iyad Ahmed is currently testing the transition from numerically optimized beam designs to full-scale physical components.

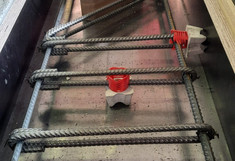

The first test beams were successfully demoulded this week at Kirchdorfer Concrete Solutions — many thanks for the fantastic collaboration!

These beams will now undergo extensive mechanical testing to verify the precision of the underlying digital design models. Various beam geometries and spans are being evaluated to enhance structural performance.

Some of the upcoming beams will even be used for the deck slab of our new Robot Lab in Groß-Enzersdorf!

But before large-scale tests can take place, we’re focusing on the material side: Cubes, cylinders, and prisms are currently being produced for standardized testing. These samples will provide key data on strength, stiffness, shrinkage, and durability, ensuring the structural testing is both reliable and meaningful.

This work forms the foundation of responsible, data-driven innovation in construction — and we’re excited to share more insights soon on how these results integrate into our digital design and automation workflow.