Productivity and material efficiency in construction are much lower when compared to other industries. In addition, there is an increasing shortage of craftsmen in the sector. To counteract these problems, an increased automation process in planning and construction is imperative. A fundamental basis for this are repeatable processes in planning and production that often lead to monotonous construction as for example in the 1970s. In contrast to this monotony stands the current high-quality building culture, which is characterized by a high degree of individuality, which in turn is in contrast to automation. In order to create a solid basis for the development of a modular building system that can be optimized and produced automatically without any problems, it is crucial to evaluate the needs and determine the requirements with regard to the individuality of the users. Currently, the Institute is researching the basics for a better understanding of this topic.

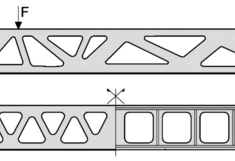

Furthermore, automated design and optimization strategies for concrete components (beams and ceiling elements) are being developed. Special attention is given to simplification and generalization of the optimization to ensure real efficiency. This development allows the optimisation to ensure real efficiency. This development allows the industry to no longer have to choose between a resource-efficient and a cost-efficient design by automatically designing modular yet adaptable structural elements that can be manufactured in automated way.

Parallel to automated structural optimisation is research into the possible automation of manufacturing processes. Compared to current automated processes known from the precast industry (e.g. double wall production), productivity should be significantly increased by using multiply 6-axis industrial robots that can preform several tasks simultaneously. By providing automated formwork systems for statically optimized slab and beam constructions, the current state of the art can be surpassed. With regard to the required formwork, a strategy for a simple and ultimately automated geometry change is being developed as well as a method for positioning and fixing the elements.

Contact:

Publications:

- Reichenbach, S., Kromser, B. State of Practice of Automation in Precast Concrete Production. Journal of Building Engineering. Nov 2021. DOI: 10.1016/j.jobe.2021.102527

- Stoiber, N; Kromoser, B Topology optimization in concrete construction: a systematic review on numerical and experimental investigations. STRUCT MULTIDISCIP O. 2021; 64(4): 1725-1749

- Stoiber, N; Kromoser, B (2021): Pushing concrete material usage to the limit: Weight optimised, 3D printed concrete girders with external reinforcement.[ International fib Symposium - Conceptual Design of Structures 2021, Solothurn, SWITZERLAND, SEP 16-18, 2021] In: FIVET, C; D'ACUNTO, P; FERNANDEZ RUIZ, M; OHLBROCK, P (Eds.), Proceedings of the International fib Symposium on the Conceptual Design od Structures ; ISBN: 978-2-940643-12-7