Advanced constitutive modeling of thermosetting adhesives

SUPERVISOR: Matthias NEUNER

PROJECT ASSIGNED TO: Luka MITROVIC

Structural thermosetting adhesives, such as rubber-toughened epoxy resins, are widely used in different engineering branches due to their high strength and stiffness, excellent adhesion to diverse substrates, and high chemical resistance. Compared to traditional fastening methods, adhesive bonding offers distinct benefits, such as a high strength-to-weight ratio, the ability to join dissimilar materials, and cost-efficiency, that align with the principles of lightweight design, sustainability, and energy efficiency.

To ensure long-term durability and safety of structural bonding applications, it is essential to properly dimension the adhesive joint for the intended service life and conditions. Numerical modeling enables prediction of the adhesive layer’s mechanical response under various loading conditions and design parameters, thereby supporting joint optimization and guiding the experimental studies to target only critical cases. The starting point for an accurate numerical prediction of joint behavior is a bulk material model that accurately describes the complex response of the adhesive.

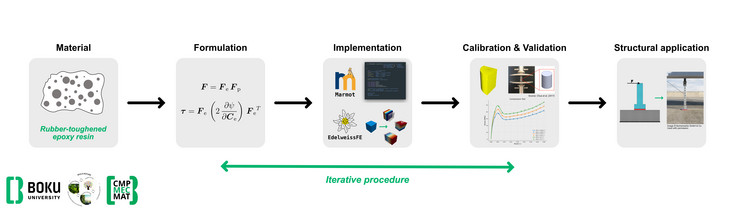

The goal of this dissertation is to develop a comprehensive finite-strain, time-dependent, thermo-mechanical bulk material model for rubber-toughened adhesives, which will be fully implemented in a finite element framework and validated at both material and structural levels.

By accurately accounting for stiffness and strength, large inelastic deformations due to excessive loads, damage initiation and propagation, as well as the time- and temperature-dependent effects of the material, this model will serve as a robust tool for simulating and optimizing joint design in practical engineering applications.