Process Optimization for Low-Density Wood-Fiber Insulation Boards using Carbohydrate-Based Adhesives

SUPERVISOR: Rupert WIMMER

PROJECT ASSIGNED TO: Ondřej FIEDLER

The transition to carbon-storing building materials is currently limited by the reliance of wood-fiber insulation on fossil-based synthetic binders. This research addresses the challenge of replacing conventional resins with sustainable carbohydrate-based thermosetting adhesives within the dry-process production chain. The core hypothesis is that synthetic binders can be effectively substituted through a targeted optimization of the manufacturing parameters to accommodate the specific behavior of carbohydrate-based chemistry.

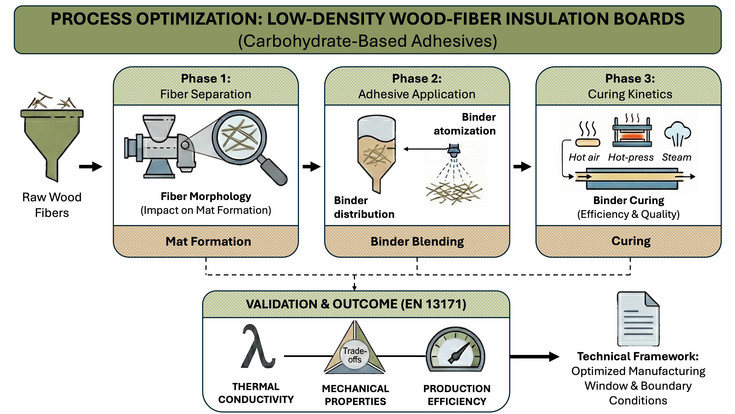

The methodology consists of a systematic investigation of three critical process phases. First, the fiber separation and preparation stage is analyzed to determine the impact of fiber morphology on mat formation. Second, the adhesive application phase focuses on the atomization of the carbohydrate binder, evaluating how binder distribution influences the final mechanical properties of the low-density structure. This is supported by an analysis of the binder's curing kinetics to establish the conditions for optimal curing. Finally, the research evaluates the integration of various thermal curing methods to compare their efficiency and impact on the product's final quality.

The performance of the resulting insulation boards is validated against the relevant European standard for wood-fiber insulation (EN 13171). The study focuses on the trade-offs between thermal conductivity, internal bond strength, and production efficiency. The outcome of this PhD project is a technical framework that defines the precise manufacturing window and boundary conditions—including fiber characteristics, atomization parameters, and curing profiles—specifically optimized for the industrial application of carbohydrate-based binders.