Automated production process for structure-optimised concrete elements

SUPERVISOR: Benjamin KROMOSER

PROJECT ASSIGNED TO: Iyad AHMED

Concrete, known for its exceptional properties and ability to create resilient, high-strength structural elements, is one of the most widely used materials globally. However, one of its primary components, Portland cement, significantly contributes to environmental pollution through CO2 emissions during its manufacturing process. Producing one ton of cement typically releases approximately one ton of CO2. Given the link between rising CO2 levels and climate change, the concrete construction industry must consider adapting its materials or usage to become more environmentally friendly. Resource efficiency in concrete construction can be approached at three levels: material, structure, and fabrication. This research focuses on structural optimization, particularly the design of resource-efficient structural elements using topology optimization.

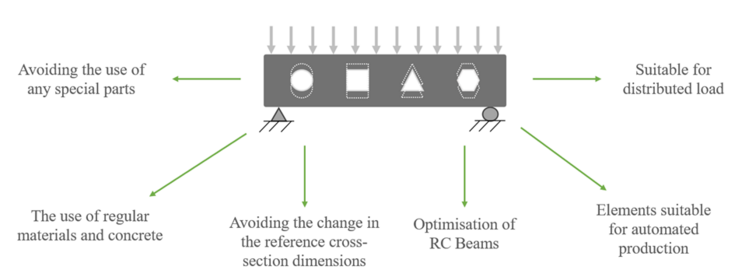

The research has two main objectives: understanding the behavior of optimized reinforced concrete (RC) beams with different void shapes under loads and developing a simplified strategy for their topology optimization. The study excludes special parts, uses regular concrete, and focuses on RC beam construction elements for direct applicability. Components chosen must be suitable for automated production and withstand distributed loads. Figure 1 summarizes the boundary conditions.

Figure 1: Summary of the boundary conditions.