Automated production process for structure-optimised concrete elements

SUPERVISOR: Benjamin KROMOSER

PROJECT ASSIGNED TO: Peter GAPPMAIER

The increasing resource consumption and man-made CO2 emissions, with the construction industry being one of the main contributors, significantly impact our environment and lives in form of climate change, supply shortages and price increases. The large lever of the building sector makes it inevitable to development innovations to eventually transition into a sustainable construction industry. Assessing the current state of practice, it can be said that concrete is the most widely used building material worldwide. This can be traced back to its good mechanical properties, high availability, free formability, low costs and high durability. Unfortunately, the production of concrete, specifically the binder cement, releases comparatively high amounts of CO2, making concrete construction one of the main CO2 emitters worldwide. When additionally assessing the economic efficiency within concrete construction, great potential is definable, especially through automation of specific processes. To counteract the increase in resource consumption and reduce emissions, a optimisation of structures should further be considered, with e.g. concrete being placed only where it is needed for static reasons. A targeted use of building materials and thus an increase in the efficiency is necessary for environmentally friendly construction, an approach pursued not only within this research project but through the entirety of the research conducted under the supervision of Prof. Benjamin Kromoser.

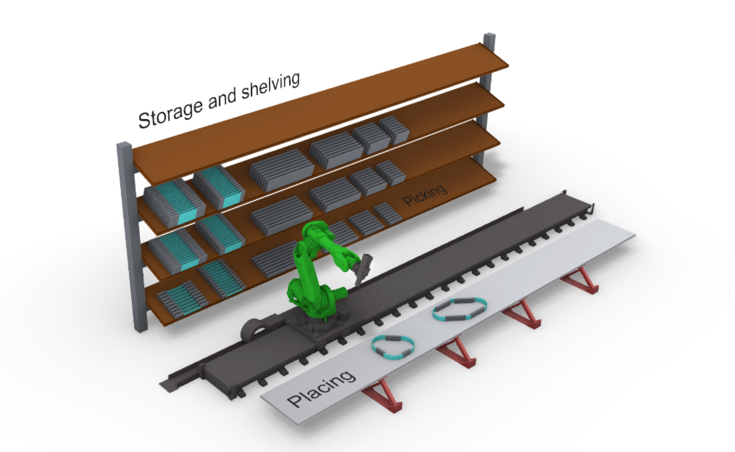

The long-term motivation and goal of the present research project is the development of a future-oriented automated production process for structurally optimised concrete components. Compared to current automated processes, as known from the precast industry, productivity is to be increased through the use of several 6-axis industrial robots that can perform different tasks simultaneously. This requires a formwork system that can be laid automatically and offers a wide variety for openings in concrete components. The presented approach does not only consider the economic aspects of robot integration within the precast construction process but also the environmental aspects in regard to efficient use of materials and sustainable shuttering systems for optimised structures.

Fig 1: Production cell with a 6-achs-industrial robot – visionary picture.

Fig 2: Opening in concrete made with modular assembled formwork.