Investigation of alternative wood species and optimized processes for strand-based unidirectional wood panels for mass timber materials

SUPERVISOR: Johannes Konnerth

PROJECT ASSIGNED TO: Lukas Malzl

Timber construction recently showed its suitability for multi-story buildings through many flagship projects (e.g. HoHo, etc.). Besides the substitution of highly energy-intensive materials, the utilization of wood for construction purposes is necessary to meet rising future needs for building materials. An efficient dimensioning of the components and a significant improvement of the yield of used wood resources are vital for this purpose, since currently successful wood products for construction like cross-laminated timber are produced from sawn and planned timber and therefore have a low yield (30-40%).

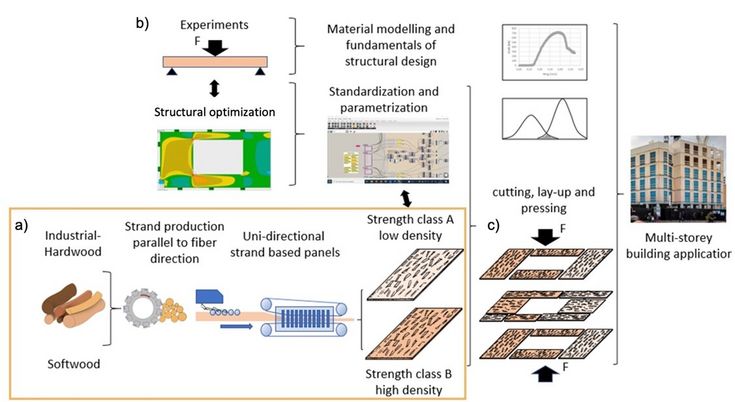

Within the frame of the THINK.WOOD.INNOVATION project funded by BMLRT, the present project part will lay the technological base for 7-20 cm thick, plate-shaped engineered wood products made from unidirectionally arranged strands (i.e. thin long veneer stripes). These will subsequently be glued together at right angles to provide strength in both main directions of the combined multi- layered panels, the needed final thickness, and swelling mitigation. Strands can be produced with high yields from a wide range of tree sizes and shapes, which enables the efficient usage of deciduous wood and thinnings. Deciduous (e.g. beech, oak) and coniferous species (e.g. pine) or mixtures thereof will be utilized to enable the industry to cope with the changing supply owing to climate change. The unidirectional arrangement of the strands inside the single layers provide a predictable (i.e. low variance) high strength product with increased properties compared to established products (e.g. oriented strand board). A statical optimization of the panel stacks to prevalent load cases by the use of panels of different densities leads to the production of elements that only use material where it is statically needed and thereby reduces material consumption.

As the project covers a wide range of fields, the focus of Lukas Malzl lies on aspects of materials and processes (Fig.1a). Herein the suitability of different wood species for the production of strand-based unidirectional panels will be assessed. A foundation for the selection of raw materials will be laid based on the characterization of bulk wood, the process of stranding and the quality of the strands produced thereof. Relevant properties and influencing factors will be identified by broad literature research and own experiments to determine the technological potential of different wood species and their mixtures. Moreover, processes to maximize the orientation of strands, the limits of orientation, and other major influencing factors on the panel properties, e.g. densities or the used adhesives will be assessed. This fundamental research delivers vital information for subsequent project parts, like adhesion of the single layers to multi-layered panels (Fig.1b) or material modeling (Fig.1c) and thereby paves the way for a resource efficient multi-story wood construction of the next generation.

Fig.1: Graphical Abstract of the whole project:

a) strand production, alignment and adhesion to panels, b) right angled adhesion of unidirectional panels to multi-layered wall or ceiling elements c) material modeling and structural optimization