Surface Phenomena of Wood as related to Wood Disintegration Process

SUPERVISOR: Ruper WIMMER

PROJECT ASSIGNED TO: Lena Maria LEITER

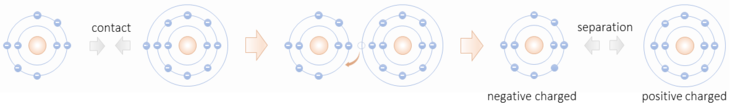

The disintegration of wood, by sawing, cutting, chipping, shredding or defibration, is one of the most important process steps in the wood industry. In all disintegration processes, friction occurs between processing tools and the solid wood or wood-based material. This friction is causing surfaces to become electrically charged due to triboelectrification (Figure 1). Charging of wood surfaces is a phenomenon that has received so far little attention, and related research in this field is almost entirely lacking.

When any surface is activated, the properties of the interface of a solid with the environment change. In this research, triboelectric activation is proposed as an innovation method of activation. It shall be approved or disapproved, to what extent triboelectric charging is showing comparable effects on surface energy levels, as compared to currently employed surface treatment technologies. It is the goal to extend the scope on basic and applied aspects of triboelectric phenomena of wood surfaces, with respect to wood processing, and various primer treatments. The environmental impact of wooden materials shall be reduced by using triboelectricity and making chemical pretreatment redundant.

The following hypothesis stated, which will be tested during the research period: (H1): A universal usable measurement method to record triboelectric charges after surface activation is achievable, (H2) After plasma treatment, wood shows the same relative changes in free surface energy and surface charging. Therefore, the measurement of surface charge can be established as a suitable method to evaluate surface energy, (H3) Various wood processing will lead to triboelectric activation. The introduced charges can be influenced by wood tools and machine settings, and (H4) Triboelectric charging is dependent on wood properties such as chemical composition, wood structure and other physical factors.

Figure 1: Principle of triboelectrification