A new resource-efficient material concept based on hardwood branches

SUPERVISOR: Johannes KONNERTH

PROJECT ASSIGNED TO: Tobias NENNING

At present, most of the demand for structurally load-bearing timber products is met by softwood logs, while the use of broadleaved hardwood in this field of application is currently only of minor importance. However, climate change adaptation of forests and woodlands is leading to a shift in vegetation to more broadleaved and mixed forest stands. For central Europe this means that forests are expected to consist of more beech trees (Fagus sylvatica) and oak trees (Quercurs robur, Quercus petraea) at the expense of Norway spruce trees (Picea abies) [1].

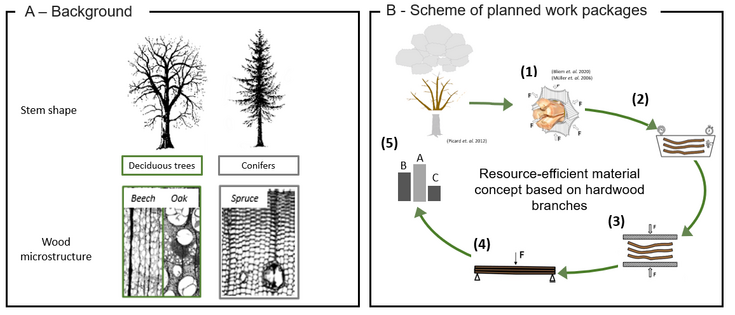

As shown in figure A, deciduous trees have a distinctly more pronounced branching morphology compared to conifers. Furthermore, from a materials science point of view, the microstructure, as well as the physical material properties of hardwood and softwood, differ significantly.

Consequently, a smaller proportion of the log assortments are being suitable for sawmill processing into timber. This demonstrates the need for resource-efficient material concepts including the non-sawable assortments. Understanding the fundamental material properties of hardwood branches is the basis for these new concepts.

Within the dissertation, a new pathway to producing strong, high-value wood composites from low-value non-sawmill grade hardwood branches is developed. The route towards this aim consists of the following work packages illustrated in figure B: (1) Splitting of wood along the grain to produce elongated macro-strands [2], (2) thermally assisted plasticisation and (3) densification/straightening. Simultaneously step (4) uses adhesive bonding to form high-value, straight fibre beam elements capable of serving as structural components e.g. in construction or automotive. After laboratory testing, the ecological and economic potential (5) of the beam elements in comparison to conventional building materials is evaluated.

[1] Schier F, Morland C, Janzen N, Weimar H (2018) Impacts of changing coniferous and non-coniferous wood supply on forest product markets: a German scenario case study. European Journal of Forest Research 137 (3):279-300. doi:10.1007/s10342-018-1111-6

[2] Bliem P, Frömel-Frybort S, van Herwijnen HWG, Mauritz R, Müller U, Teischinger A, Konnerth J (2020) Holzwerkstoff basierend auf Partikeln hergestellt mittels einer neuartigen, nicht schneidenden Zerteilungstechnologie. Holztechnologie 61 (3):30-38