Biotechnical functionalization and recycling of multicomponent materials

SUPERVISOR: Georg M. GÜBITZ

PROJECT ASSIGNED TO: Sophia MIHALYI

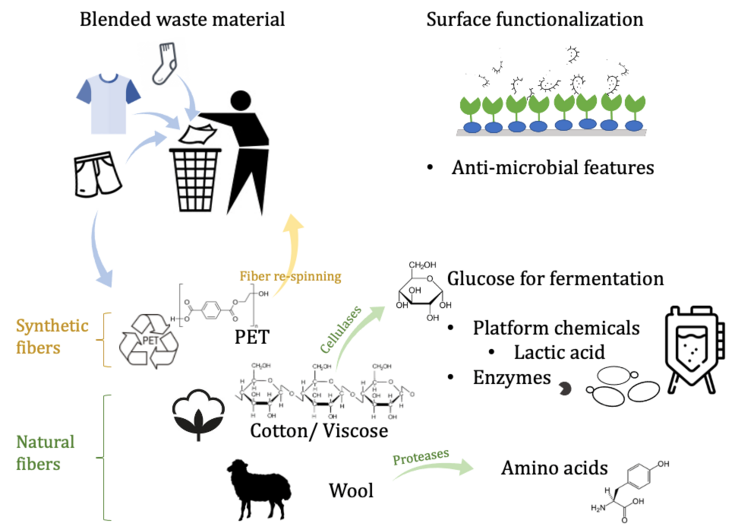

This PhD project will focus on the enzymatic functionalization and recycling of multicomponent materials and utilization of building blocks to produce new value-added products through fermentation with microorganisms such as the yeast Pichia pastoris and with Escherichia coli. The project will also be part of the EU project SCIRT (System Circularity & Innovative Recycling of Textiles) which aims to promote the development towards a circular fashion system involving novel recycling concepts [1].

The production of clothing and footwear accounts for 10 % of global greenhouse gas emissions and often toxic additives are used to impart certain functionalities [2]. Therefore, enzymatic functionalization of fibers can be implemented as an alternative to toxic chemical application for purposes such as generation of antimicrobial surfaces or increased flame retardancy [3-5].

The material surface will be functionalized by partial enzymatic hydrolysis and subsequent coupling of bioactive molecules or by identification of polymer binding peptides that can be fused to bioactive enzymes for generation of new surface properties.

Furthermore, there is urgent necessity to develop processes for recycling of textiles since 10 million tons of textile waste are generated yearly and 87 % is landfilled or incinerated in the EU and only less than 1 % is recycled to generate new clothes [2, 6]. Disposed textile materials often consist of blended fibers that make conventional recycling a challenging task. Enzymatic depolymerization results in selective hydrolysis of fiber blends and enables specific recovery of valuable building blocks and polymers from material blends under environmentally friendly conditions [7].

Textiles and packaging materials are composed of natural fibers such as from cotton, wood/viscose and wool or synthetic fibers like polyester or polyurethanes [8, 9]. In this work, cellulases will be applied for cellulose and viscose hydrolysis to glucose and separation of the abovementioned natural fibers from synthetic fibers in blended materials. Regenerated glucose can then be utilized as a substrate in fermentation processes to generate new valuable products such as lactic acid as a building-block for a bio-polyester (PLA) [10]. Beyond that, wool degradation will be performed by proteases to enable recovery of valuable amino acids from textile blends [8].

The goal of this thesis is to develop novel strategies for functionalization and recycling of multi-component materials with a major focus on textiles. Additionally, possible new enzymes and binding peptides will recombinantly be expressed to enhance polymer decomposition and introduce novel surface characteristics.

Taken together, the aim of this work is to contribute to the development towards a circular bioeconomy in the textile industry by recycling of non-reusable textiles into valuable products and avoidance of landfilling of reusable polymers to reduce greenhouse gas emissions.

Figure 1: Schematic representation of the recycling and valorization concept of textile blends and a generated antimicrobial surface (blue circles represent polymer-binding peptides, green three-quarter circles represent coupled enzymes displaying antimicrobial activity and microbes are represented by partial black hairy rods).

References

[1] SCIRT (System Circulartity & Innovative Recycling of Textiles). https://scirt.eu/project/. (Accessed 26.10. 2021).

[2] European Parliament. https://www.europarl.europa.eu/news/en/headlines/society/20201208STO93327/the-impact-of-textile-production-and-waste-on-the-environment-infographic. (Accessed 26.10. 2021).

[3] F. Quartinello, K. Kremser, S. Vecchiato, H. Schoen, R. Vielnascher, L. Ploszczanski, A. Pellis, G.M. Guebitz, Increased Flame Retardancy of Enzymatic Functionalized PET and Nylon Fabrics via DNA Immobilization, Frontiers in Chemistry 7(685) (2019).

[4] F. Quartinello, C. Tallian, J. Auer, H. Schön, R. Vielnascher, S. Weinberger, K. Wieland, A.M. Weihs, A. Herrero-Rollett, B. Lendl, A.H. Teuschl, A. Pellis, G.M. Guebitz, Smart textiles in wound care: functionalization of cotton/PET blends with antimicrobial nanocapsules, Journal of Materials Chemistry B 7(42) (2019) 6592-6603.

[5] B. Thallinger, M. Brandauer, P. Burger, C. Sygmund, R. Ludwig, K. Ivanova, J. Kun, D. Scaini, M. Burnet, T. Tzanov, G.S. Nyanhongo, G.M. Guebitz, Cellobiose dehydrogenase functionalized urinary catheter as novel antibiofilm system, J Biomed Mater Res B Appl Biomater 104(7) (2016) 1448-56.

[6] Neue Bio-recycling-Verfahren dreifach ausgezeichnet, 2021. https://boku.ac.at/news/newsitem/65838.

[7] B. Piribauer, A. Bartl, Textile recycling processes, state of the art and current developments: A mini review, Waste Management & Research 37(2) (2019) 112-119.

[8] F. Quartinello, S. Vecchiato, S. Weinberger, K. Kremenser, L. Skopek, A. Pellis, G.M. Guebitz, Highly Selective Enzymatic Recovery of Building Blocks from Wool-Cotton-Polyester Textile Waste Blends, Polymers 10(10) (2018) 1107.

[9] F. Quartinello, K. Kremser, H. Schoen, D. Tesei, L. Ploszczanski, M. Nagler, S.M. Podmirseg, H. Insam, G. Piñar, K. Sterflingler, D. Ribitsch, G.M. Guebitz, Together Is Better: The Rumen Microbial Community as Biological Toolbox for Degradation of Synthetic Polyesters, Frontiers in Bioengineering and Biotechnology 9(500) (2021).

[10] S. Vecchiato, L. Skopek, H. Russmayer, M.G. Steiger, A. Aldrian, B. Beer, E. Herrero Acero, G.M. Guebitz, Microbial production of high value molecules using rayon waste material as carbon-source, New Biotechnology 51 (2019) 8-13.