Renewable carbohydrate-based adhesive development for wood industry applications

SUPERVISOR: Johannes KONNERTH

PROJECT ASSIGNED TO: Marek KALANIN

The wood-based panel industry is a cornerstone of the circular bioeconomy, with the annual production exceeding 70 million m3. However, the sustainability of these materials is currently undermined be their heavy reliance on the fossil-based adhesives, such as urea-formaldehyde (UF) resins, which create a health concerns due to its formaldehyde emmisions. Within the frame of project SUSBOARD funded by European Union, this doctoral research aims to provide a novel adhesive technology by developing a cost-competetive, 100% bio-based, and formaldehyde-free adhesive designed for the wood-based panels, sepecifically particle boards (PB) and medium density fibreboards (MDF). By substituing fossil-based binders with renewable carbohydrate-based alternatives, the research seeks to meet rising needs for sustainable materials for furniture industry.

The focus this doctoral project lies on a bridging the development pf the novel adhesive and its integration into a PB production. The sustainability of various carbohydrate-derived precursors for the production of the wood based panels is assessed through a combination of a chemical modification and laboratory-scale manufacturing of a PB. A foundation for selection of bio-based materials is laid based on the charaterization of their reactivity and the resulting bonding strength. Relevant influencing factors are indentified be a broad literature reasearch and own experiments to determine the technological potential of these green binders compared to established synthethic benchmarks (e.g. UF resins).

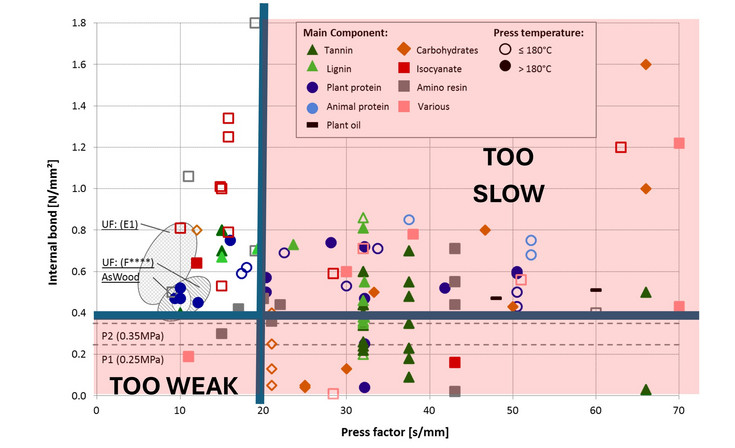

Moreover, the research investigates the interaction between the carbohydrate-based adhesive and wood particles to optimize industrial processing parameters to ensure that the developed adhesive systems are neither „too weak“ nor „too slow“ for commercial viability (Fig. 1). This research delivers vital information for scaling up bio-based binders to an industrial level and paves the way dot a resource-efficient, formaldehyde-free generaton of wood products that can be seamlessly integrated into modern production.

Fig. 1 Overview of the internal bond strengths as a function of pressing factor for adhesives used for particleboard manufacture [1]

[1] Solt, P. et al. (2019) Technological performance of formaldehyde-free adhesive alternatives for particleboard industry, International Journal of Adhesion and Adhesives. journal-article, pp. 99–131. https://doi.org/10.1016/j.ijadhadh.2019.04.007.