Advanced cellulose characterization for fiber spinning

SUPERVISOR: Antje POTTHAST

PROJECT ASSIGNED TO: Markus EDER

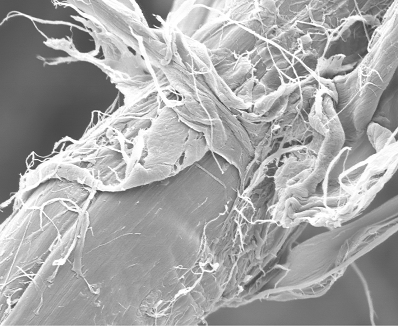

Cellulose is a renewable raw material with excellent mechanical and physical properties and high availability for a steadily growing number of technical applications. Traditionally, the important products from cellulose are paper-based products and regenerated fibers. One challenge associated with the use of cellulose in fiber production is its processing behavior. Regenerated cellulose from the viscose or lyocell process are used to produce textile fibers, technical filaments, and films.

Advanced chemical characterization of the various celluloses available can be of great benefit in defining the scope of regenerated fibers and addressing process control issues. Therefore, there is a high demand for analytical methods suitable to overcome the difficulties in structural analysis of the different cellulose sources. Available analytical methods are usually aimed at the direct characterization of certain polymer properties, i.e., the molecular weight distribution, hemicellulose content, crystallinity, or functional group profiles. However, the dissolution behavior of celluloses in different solvents is often not directly correlated to those classical analytical data and requires a deeper understanding of morphology, chemistry, and by-products depending on the origin of the cellulosic material.

This ABCT project, performed in collaboration with an industrial partner, will contribute to a better understanding of structure–property relationships in cellulose processing.