Extraction, modification and analysis of lignin from residual wood streams

SUPERVISOR: Antje POTTHAST

PROJECT ASSIGNED TO: Stefan GRASBÖCK

Lignin accounts for up to 30% in plants and is only surpassed by cellulose and consequently the world's second most abundant bio-polymer. Overall, it is a complex, heterogenous and amorphous bio-polymer consisting of three phenolic monomers.

In the plant, lignin contributes to the cell wall stiffness, hydrophobicity and the protection against pathogens. As a result, plants can easily grow on land and trees are able to reach their known hights.

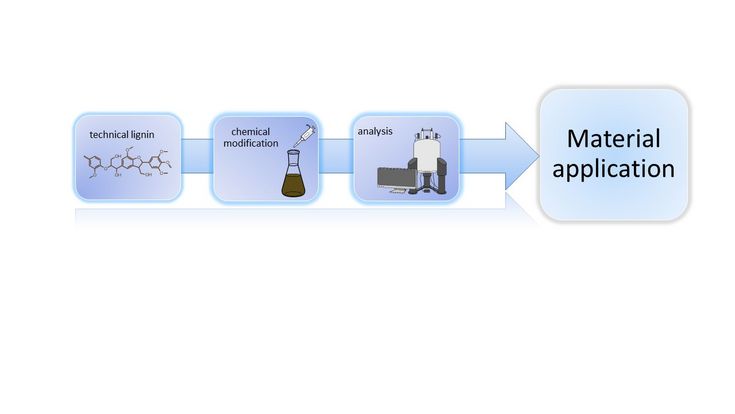

We can use lignin as an additive in adhesives and resins for plywood, particleboards, laminated veneer lumber, paper laminations and insulation materials. Moreover, we can even use it for soil improvement, UV protection and in cosmetic applications. Sounds good, right? In theory, you can do everything with lignin, in practice however, lignin is just a by-product of the pulp and paper industry. The harsh pulping conditions during paper making lead to a modified type of lignin – the so-called “technical lignins”. While pulping, native lignin undergoes various types of reactions that result in disadvantages properties – limiting valorisation of technical lignins in many areas. Nevertheless, we are not giving up on lignin and will look for ways to use it as a binder in the wood processing industry.

In this project, we hope to gain a better understanding of efficient lignin modification – leading to an improved processing of lignocellulosic biomass and enhancing the valorisation of lignin in a wide field of applications.