Stabilizing lyocell dopes for safe and efficient cellulose fiber production

SUPERVISOR: Thomas ROSENAU, Hubert HETTEGGER

PROJECT ASSIGNED TO: Olga IVANOVA

One of the most important areas of industrial processing of cellulose is the production of manmade cellulosic fibers from wood-derived high-quality dissolving pulp as a raw material.

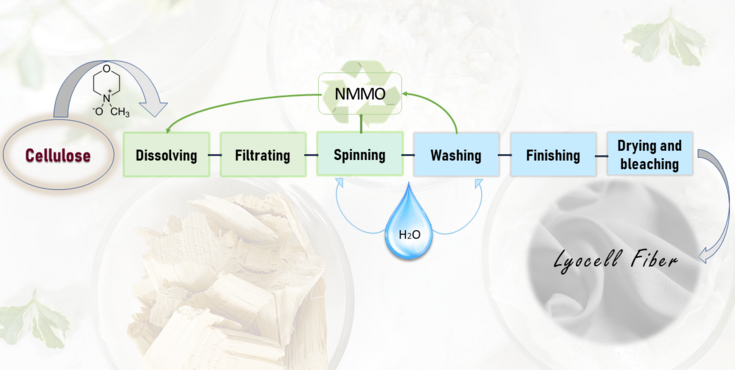

In the last 30 years, the lyocell process has developed into an increasingly important alternative to the dominating viscose process for the production of high-tech fibers. It is based on the physical dissolution of cellulose in aqueous NMMO (N-methylmorpholine N-oxide). The lyocell process has many advantages such as biodegradability of the solvent, non-toxicity, recyclability of the process chemicals, no derivatization, and the use of water in the regeneration bath. However, NMMO is a strong oxidant and tends to autocatalytic degradation, especially at high process temperatures, thus the spinning dope (aq. NMMO + cellulose) must be stabilized to prevent adverse reactions.

The most important and industrially utilized stabilizer is propyl gallate, but it has certain limitations. With these considerations in mind, this project aims to find alternative stabilization agents and systems for the production of modern high-tech cellulosic fiber materials by the lyocell process. The project further involves an in-depth analysis of reaction pathways and degradation/aging mechanisms as well as aspects of recyclability.