Enzymatic synthesis of value-added products from lignin

SUPERVISOR: Georg M. GÜBITZ

PROJECT ASSIGNED TO: Sebastian-Alois MAYR

Increasing environmental pollution concerns are directing efforts towards the development of green chemistry technologies and efficient exploitation of renewable resources. Lignin, a product from the wood pulping process, is one of the major chemical constituents of woody biomass and second most abundant biopolymer on earth, surpassed only by cellulose. Annually, more than 50 Mio tons of lignin are produced, but only less than 2 % are used in value-added applications. [1]

Therefore this thesis aims to develop and characterize novel enzyme-based processes to use lignin in value-added applications, such as in paper coating & sizing formulations.

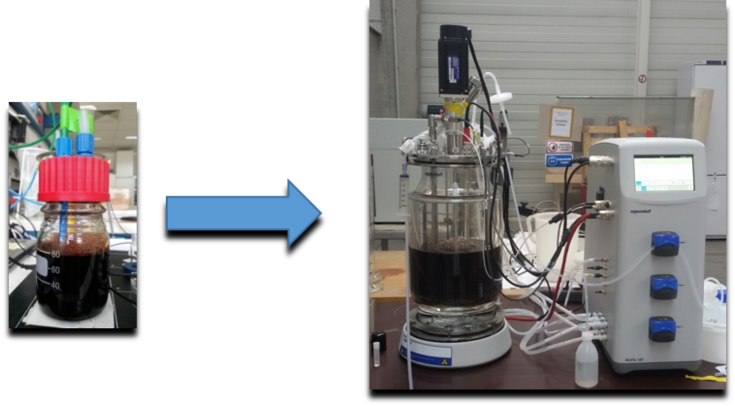

For the use of lignosulfonates in paper coatings the project aims an industrial implementation on pilot scale. Therefore the development will be performed in close cooperation between BOKU and Sappi Gratkorn (within Polizyme as a Flippr² associated project).

Extensive polymerization of lignosulfonates with laccases results in highly viscous to gel-like materials and solid materials upon drying. However, the resulting material is strongly dependent on the composition and pretreatment of the starting material, on suitable process conditions like pH, sufficient oxygen supply, dry substance of lignin, enzymatic activity and temperature. [2][3]

For that reason the polymerization process needs to be characterized and optimized in order to tailor the properties of enzymatically modified lignin into specific high-value products.

[1] Varanasi P et al Biotechnology for Biofuels 2013, 6, 14.

[2] Ortner A et al Process Biochemistry 2015, 50, (8), 1277-1283.

[3] Huber D et al ACS Sustainable Chemistry & Engineering 2016, 4, (10), 5303-5310.