Thermal and aging resistance of cellulosic pulp for special papers

SUPERVISOR: Thomas ROSENAU

PROJECT ASSIGNED TO: Paul JUSNER

Cellulose, featuring outstanding mechanical and physical properties as well as high availability, is a renewable resource for a steadily expanding range of technical utilisations. Nonetheless, an issue that comes along with using this natural resource for technical applications is its degradation behaviour. Some of the most important products based on cellulose are traditionally paper and regenerated cellulose fibres. Permanence of paper used as an information carrier is a central requirement of librarians and archivists. More sophisticated utilisations of paper such as insulating paper in electrical power transformers require in addition stability under elevated temperatures and predictable life spans. Thermal stability is an issue as well when cellulose fibres are used as reinforcement phase in thermoplastic matrices because of high processing temperatures.

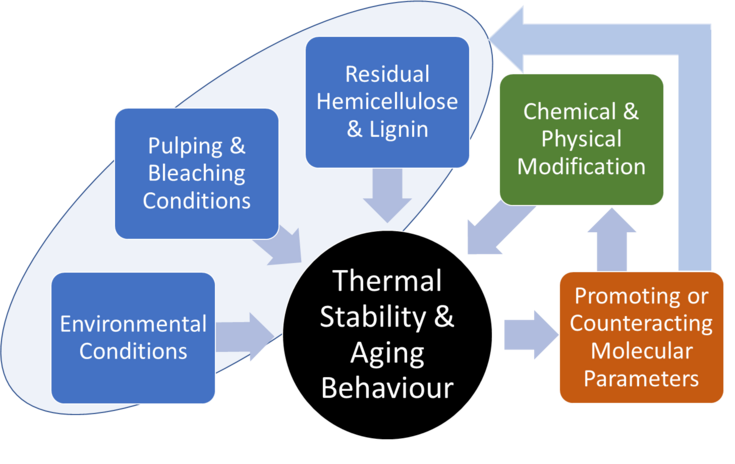

A variety of degradation mechanisms are contributing to chain scission of cellulose molecules. If cellulosic pulp processed into paper surpasses a certain level of degradation, mechanical properties would be lost, and optical properties deteriorated. All these degradation mechanisms are driven by environmental factors such as temperature, humidity, availability of oxygen or light. Furthermore, material characteristics like acidity of the paper, amount of residual lignin or hemicellulose, and crystallinity of cellulose affect the degradation rate. Consequently, pulping and bleaching conditions as well as the cellulose source play a decisive role for the thermal stability and aging behaviour of paper. This complex system requests the determination of key molecular parameters of pulp affecting these properties in order to allow a smart material and process selection in case high degradation resistance is required. Subsequently, based on this knowledge modification concepts of cellulose fibres will be investigated to tailor the pulp and paper properties according to demand. In general, this ABCT project conducted in cooperation with Mondi Frantschach GmbH will contribute to a better understanding of the processes ongoing during pulp degradation and eventually lead to the development of a set of methods to obtain cellulosic products featuring enhanced thermal and aging resistance.