Optimization of industrially applicable microbial 1,3-propanediol and 3-hydroxypropionic acid production

SUPERVISOR: Diethard MATTANOVICH

PROJECT ASSIGNED TO: Irene TOMICO CUENCA

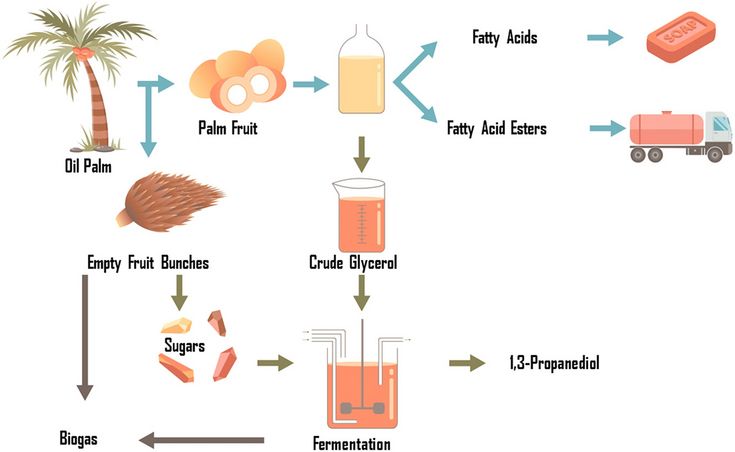

Biodiesel consists of fatty acid alkyl esters and is produced via the transesterification of long chain fatty acids, derived from vegetable oil, with methanol. The principal by-product of this process, which makes up to 10% of biodiesel production, is crude glycerol. Since its purification is rather unsustainable, microbial upgrading to value-added products opens new opportunities. Lentilactobacillus diolivorans metabolizes glycerol to balance its electron household by reducing the intermediate 3-hydroxypropione aldehyde to 1,3-propanediol (1,3-PDO) or oxidizing it to 3-hydroxypropionic acid (3-HP). This species of Lactobacillus is a very effective natural producer of 1,3-PDO, mainly used as a building block for the production of different polymers like polymethylene terephthalate and has other different industrial application. Moreover, L. diolivorans also shows potential for the production of 3-hydroxypropionic acid, which is considered one of the top twelve value-added platform compounds from biomass according to the US Department of Energy.

The aim of this project is the optimization of industrially applicable microbial 1,3-propanediol and 3-hydroxypropionic acid production from streams from agrichemical industries. The current process renders good final titers, but the productivity needs to be increased. The main focus of the project will be the use of different bioprocess strategies to improve the productivity of the two compounds of interest. Moreover, the development of a fully integrated bioprocess for the purification of 1,3-PDO, as well as the separation and purification of the by-product 3-HP is attempted.

Image source: Hannes Russmayer, Michael Egermeier, Hans Marx, Viktoria Leitner, Michael Sauer, Entirely oil palm-based production of 1,3-propanediol with Lentilactobacillus diolivorans, Environmental Technology & Innovation, Volume 29, 2023, 103024,

ISSN 2352-1864,

doi.org/10.1016/j.eti.2023.103024