Power input in miniaturized systems for continuous operation

SUPERVISOR: Astrid DÜRAUER

PROJECT ASSIGNED TO: Ignacio MONTES SERRANO

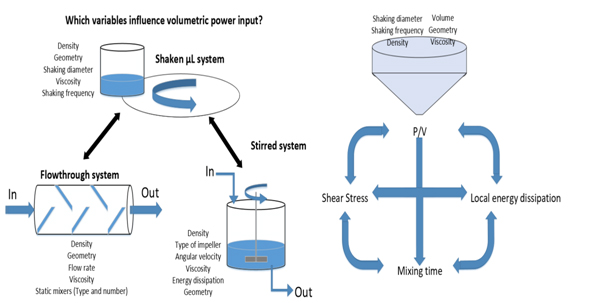

The versatility of microtiter plates due to the large number of parallel “reactors” with volumes in the µL scale has made them an indispensable equipment for both - up and downstream when it comes to condition screening and process design. However, even though microtiter plates are commonly used in laboratories for process development, their hydrodynamic behaviour is not entirely understood yet. Also scale-up model that allow the transfer of conditions directly from the shaken microwell to different continuous processes such as stirred tank or continuous flow through tubular devices are currently not available. The strategy that has granted the best results in scale-up is the conservation of a similar volumetric power input, since this parameter determines the way the system will move, as well as having a direct link with the shear stress, shear rate and local energy dissipation. All of them are crucial parameters for process design.

In this PhD thesis, experimental data as well as Computer Fluid Dynamics (CFD) are utilised to describe the behaviour displayed by different formats of shaken microtiter plates, ranging from 96-wells with a diameter of seven millimetres up to 6-wells with a diameter of thirty-six millimetres. The use of CFD also concedes the study of parameters such as the study of velocity fields and vorticity in different sections of the wells, making it possible to do an in-detail study on how such variables can affect the process design and the presence of dead volumes

The main aim of the thesis is to develop mathematical models to predict the volumetric power input in shaken microwells and correlate those to continuous flow through tubular devices systems or granting a proper scale-up between microscale and bench scale.

Figure 1. Representation of the linkage between systems when it comes to process design and what variables influence the hydrodynamic behaviour, as well as how that behaviour is directly connected to the shear stress, the local energy dissipation and the mixing

This project is developed as part of the ITN Continuous Downstream of Biologics (CODOBIO), funded by the European Union under the Marie Curie- Sklodowska framework.