Digital design and automated construction 2025

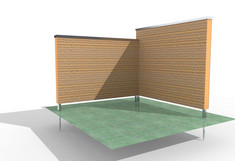

As part of the course Digital Design and Automated Construction, 12 students designed, fabricated, and assembled a timber frame wall system — relying entirely on digital design and manufacturing workflows.

The process was driven by robotic milling and automated assembly, supported by laser scan-based quality control for precise verification of each component.

The wall elements were constructed using traditional dovetail joints and wooden dowels — completely metal-free. Mounted on removable screw foundations, the system is fully reversible and reusable.

To complete the project, a rough-sawn timber cladding was added using Lignoloc wooden nails, reinforcing the commitment to circular, metal-free construction principles.

A big thank you to everyone involved in making this possible!