Economic and ecological assessment of clean water for biopharmaceuticals

SUPERVISOR: Alois JUNGBAUER

PROJECT ASSIGNED TO: Alessandro Luigi CATALDO

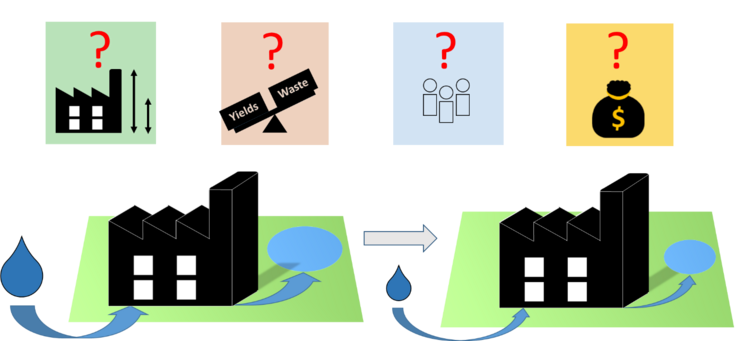

Economic benefits are among the main goals of process development. The scientific challenges in economic and environmental modelling of biotechnological manufacturing processes is its complexity. Production modes such as batch or continuous may also affect clean room classifications, validation efforts and sterile utility requirements. Especially the consumption of water with different purity grades has an important role in every biomanufacturing process. In 2018 Budzinski et al. introduced a metric, which previously only was applied in the production of small molecules, the process mass intensity (PMI). The PMI shows the total amount of required resources (in kg per kg produced product). This metric considers process- and cleaning water, materials and consumables as resources. The average PMI in the production of antibodies is about 7,000 kg/kg product, whereby over 90 % of this value is dedicated to water. In my thesis project I want to evaluate how ecological goals, for instance by reducing the PMI, and economic benefits can be combined. Furthermore other correlations of manufacturing parameters should be considered, like footprint, labour demand or yield variations. This thesis focuses on sustainability in the field of biotechnology, especially in the establishment of metrics and water related production parameters, which can later be applied in existing processes.