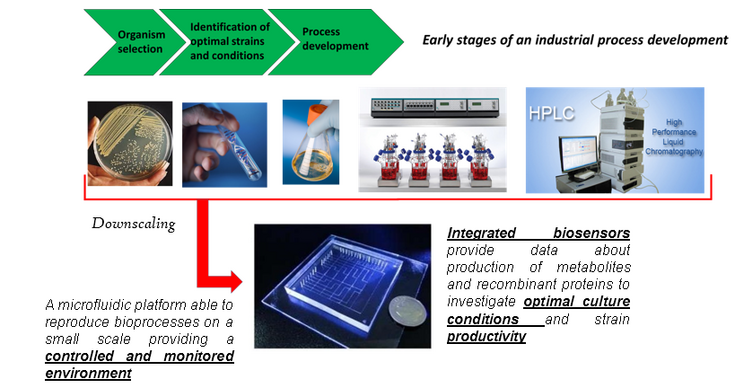

Microfluidic platform for downscaling fermentation and for screening engineered strains

SUPERVISOR: Diethard MATTANOVICH

PROJECT ASSIGNED TO: Damiano TOTARO The development of a biotechnological process depends on the optimization of a number of parameters, such as the strain, the cultivation mode, pH, temperature, dissolved oxygen concentration, growth behaviour and others. Establishing the right protocol requires a huge amount of work and time, therefore it is not surprising that there is an increasing demand for novel systems able to perform parallel processes and high-throughput analyses.

Microfluidics - and the miniaturization of laboratory instruments in general - has become a powerful tool for biotechnology and its applications have constantly increased in the last decade. This project aim is a multi-module microfluidic platform with a cultivation system and integrated sensors for operational and product parameters monitoring able to screen multiple strains. Small-scale devices provide us with the opportunity to have a better control of the whole experimental system and to reduce cost in the early stage of industrial process development.

The microfluidic platform will be mainly composed of a cultivation module, where the cultures of engineered strains take place, and a sensing module for the detection of the operational parameters (pH, biomass and dissolved oxygen) of the cell culture and the concentration of the product of interest (either a small molecule or a recombinant protein). In order to achieve this purpose and to reproduce common laboratory experiments on a sub-millilitre scale, several novel technologies coming from nanotechnology and biosensoristic fields will be combined and tested.