Influence of fermentation strategies and scale effects on Fab fragment production in Escherichia coli

SUPERVISOR: Gerald STRIEDNER

PROJECT ASSIGNED TO: Florian MAYER

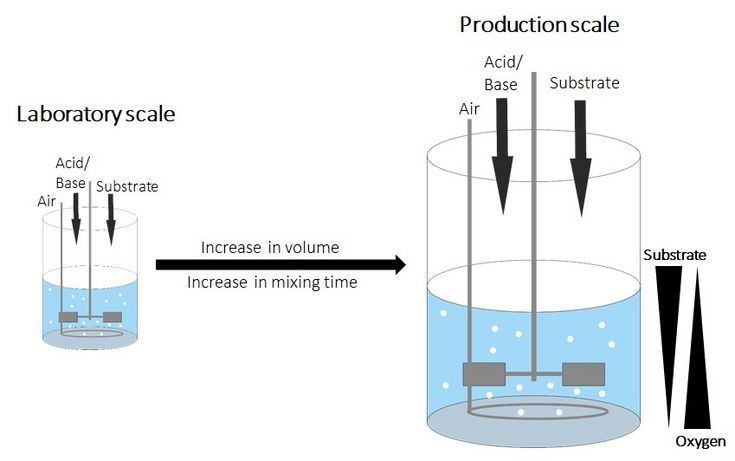

In biotechnological industry cultivation vessels of up to several hundred m3 are used for production. However, process development is done in small scale, which could lead to problems during scale up. An almost inevitable issue is the increase of mixing time in large scale and therefore the development of substrate and oxygen gradients in the tank (Figure 1). The production organisms react to this inhomogeneities and in result, process performance as well as product quality can be affected negatively.

Figure 1: Schematic illustration of scale-up problem

During this PhD project a scale-down approach will be used to simulate the conditions from large scale in small scale. Therefore, a plug-flow reactor (PFR) will be connected to a 20 L stirred tank bioreactor to mimic the gradients the cells are exposed to during industrial production (Figure 2).

Figure 2: Schematic illustration of scale-down approach

For scale-down experiments different strains of Escherichia coli, producing Fab antibody fragments, will be used. It will be investigated which production strains are more robust to the gradients and therefore better suited for large scale production. In this perspective an important criterion is the amount of non-canonical amino acid misincorporation in the Fab product, which is described as a problem in large scale. In addition, the effect of fermentation strategies and how the scale effects influence the connection between upstream and downstream will be investigated as well.

The outcome of the project should give information on how conditions at large scale affect industrial relevant Fab antibody fragment production processes. It could also deliver possible solutions by identifying more robust E.coli strains and at the end help to improve process scale-up.

The project is part of the CD Laboratory for production of next-level biopharmaceuticals in E. coli and financed by the Christian Doppler Forschungsgesellschaft and Boehringer Ingelheim RCV GmbH & Co KG.